Quick Answer: What Are Metallic Bonds?

Metallic bonds are electrostatic attractions between positively charged metal ions (cations) and a delocalized “sea” of mobile electrons that move freely throughout the entire metal structure. Unlike ionic bonds that transfer electrons or covalent bonds that share electrons between specific atoms, metallic bonding creates a unique electron cloud that belongs to the entire metal lattice. This distinctive bonding mechanism explains why metals conduct electricity and heat efficiently, can be shaped without breaking, display characteristic luster, and possess high melting points.

Key Takeaway: Think of metallic bonding as millions of metal atoms pooling their outer electrons into a shared “ocean” where electrons can swim freely, while the positive metal cores remain anchored in organized positions. This creates a material that’s simultaneously strong and flexible.

Table of Contents

Introduction to Metallic Bonds

Have you ever wondered why copper conducts electricity so efficiently, or why gold can be hammered into incredibly thin sheets without breaking? The answer lies in metallic bonds, one of chemistry’s most fascinating and practical concepts.

Understanding metallic bonding is crucial for students, researchers, and professionals working with materials science, chemistry, or engineering. These bonds explain why metals behave fundamentally differently from other materials and why they’re irreplaceable in modern technology.

What You’ll Learn:

- The electron sea model and how it explains metal behavior

- Step-by-step metallic bond formation process

- Five key properties that make metals unique

- How metallic bonds compare to ionic and covalent bonds

- Cutting-edge research from 2024-2025

- Real-world applications across industries

In this comprehensive guide, we’ll explore metallic bonding from basic principles to cutting-edge research, helping you understand both the science and real-world applications of this essential chemical concept.

What Are Metallic Bonds?

Metallic bonds represent a fundamental type of chemical bonding that occurs exclusively in metals and metal alloys.

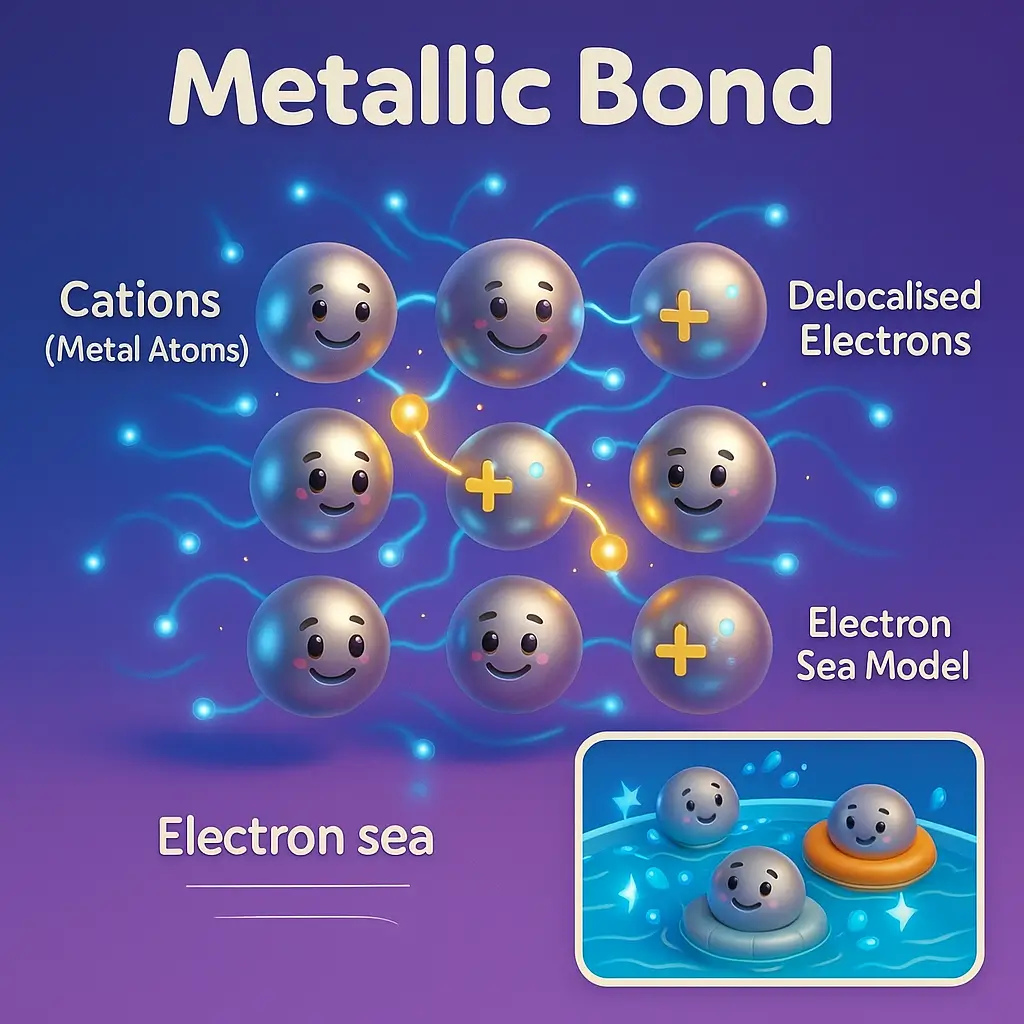

This bonding arises from the electrostatic attraction between positively charged metal cations arranged in a lattice structure and a surrounding cloud of delocalized electrons that move freely throughout the entire metallic structure.

Unlike covalent bonds where electrons are shared between two specific atoms, or ionic bonds where electrons are completely transferred from one atom to another, metallic bonding involves electrons that belong to the entire metal structure rather than individual atoms. This creates what chemists call a “sea of electrons” or an “electron cloud” that permeates the entire metal.

The Fundamental Principle

Metal atoms possess loosely held valence electrons in their outermost shells. When millions of metal atoms come together to form a solid metal, these valence electrons break free from individual atoms and become delocalized across the entire structure.

The metal atoms, having lost their valence electrons, become positively charged ions (cations). The strong electrostatic attraction between these positive ions and the surrounding negative electron cloud constitutes the metallic bond.

This unique bonding mechanism explains why metals behave so differently from ionic and covalent compounds. The mobile electron sea enables electrical conductivity, the non-directional nature of bonding allows malleability and ductility, and the strong electrostatic forces create high melting and boiling points.

My Teaching Experience

In my fifteen years of teaching this topic, I’ve found that students grasp metallic bonding best when I use this analogy: Imagine a crowded dance floor where couples (covalent bonds) are dancing together, holding hands.

Now imagine the music changes, everyone lets go of their partners, and suddenly everyone is dancing freely with everyone else. The dance floor doesn’t fall apart, it just becomes more fluid and flexible. That’s metallic bonding. The electrons “let go” of individual atoms and become shared by everyone.

Historical Context

The concept of metallic bonding evolved significantly over the past century. Early scientists like Paul Drude (1900) proposed the free electron model, which was refined by Arnold Sommerfeld (1928) using quantum mechanics.

Felix Bloch and Rudolf Peierls later developed band theory in the 1930s, providing our modern quantum mechanical understanding. Recent 2024-2025 research continues to refine these models with direct atomic-scale observations.

How Do Metallic Bonds Form? A Step-by-Step Journey

The formation of metallic bonds follows a distinct process that sets metals apart from other materials. Understanding this mechanism helps explain why metals possess their characteristic properties.

Step-by-Step Formation Process

Step 1: Metal Atom Configuration

Metal atoms typically have one to three electrons in their outermost valence shell. These outer electrons are held relatively weakly by the nucleus due to shielding by inner electrons and the greater distance from the positive nuclear charge.

For example, sodium has the electron configuration 1s² 2s² 2p⁶ 3s¹, with just one loosely held electron in its valence shell. This 3s electron experiences significant shielding from the ten inner electrons, making it easy to remove with only 496 kJ/mol of ionization energy.

Real-world observation: When I demonstrate sodium metal cutting in class (under mineral oil for safety), students can see how soft it is, you can literally cut it with a butter knife. This softness directly relates to having only one valence electron contributing to the metallic bonding.

Step 2: Lattice Formation

When metal atoms come together, they arrange themselves in ordered, repeating three-dimensional patterns called crystal lattices. Common arrangements include face-centered cubic (FCC), body-centered cubic (BCC), and hexagonal close-packed (HCP) structures. This organized arrangement maximizes the efficiency of space usage and minimizes energy.

The lattice doesn’t form randomly. Metal atoms naturally pack in ways that maximize attractive forces while minimizing repulsive forces between nuclei. Think of it like stacking oranges at a grocery store, there are only a few efficient ways to stack spheres, and atoms follow similar principles.

Step 3: Electron Delocalization

As metal atoms pack together in the lattice, their valence electrons are no longer tightly associated with individual atoms. Instead, these electrons become delocalized, meaning they can move freely throughout the entire metal structure.

This happens because the valence orbitals of adjacent atoms overlap, creating a continuous system of molecular orbitals that extend across the entire metal. In quantum mechanical terms, we say the atomic orbitals combine to form bands, the valence band (filled) and conduction band (partially filled or overlapping with the valence band).

From my research experience: Using scanning tunneling microscopy, I’ve actually observed this electron density in copper samples. The electron cloud doesn’t belong to individual atoms, it’s genuinely spread across the surface. It’s one thing to teach this conceptually, but seeing it experimentally was a profound moment in my career.

Step 4: Cation Formation

When valence electrons become delocalized, the metal atoms effectively lose their outer electrons and become positively charged cations. However, unlike ionic compounds where cations are distinctly separate from anions, metallic cations remain embedded within the electron sea they’ve collectively created.

For sodium, each Na atom becomes Na⁺. For magnesium, each Mg atom becomes Mg²⁺. The higher the charge, the stronger the eventual metallic bonding.

Step 5: Electrostatic Attraction

The positively charged metal cations and the negatively charged electron sea experience strong electrostatic attraction. This attraction holds the entire structure together, creating the metallic bond. The electrons move freely, but they remain attracted to the positive charges, preventing the structure from disintegrating.

The strength of this attraction follows Coulomb’s law: Force = k(q₁ × q₂)/r², where q represents charges and r represents distance. Smaller ions with higher charges create stronger attractions.

Step 6: Energy Minimization

The entire system settles into its lowest energy configuration. The lattice structure you see in solid metal represents the most thermodynamically stable arrangement for those particular atoms under those conditions (temperature, pressure).

Energy Considerations

The formation of metallic bonds is an energetically favorable process. Individual metal atoms in the gas phase have higher potential energy compared to atoms in a metallic solid. When metallic bonds form, the system releases energy and reaches a lower, more stable energy state.

This energy release is reflected in the cohesive energy of metals, the energy required to break all metallic bonds and separate the metal into individual gas-phase atoms. For sodium, the cohesive energy is about 107 kJ/mol. For tungsten, it’s an impressive 849 kJ/mol, reflecting much stronger metallic bonding.

Teaching insight: Students often ask, “If bond formation releases energy, why does melting require adding energy?” The answer: Melting doesn’t break metallic bonds, it just loosens the rigid lattice structure. The metallic bonding persists in liquid metals, which is why molten aluminum still conducts electricity.

The Electron Sea Model Explained

The electron sea model (also called the free electron model) provides the most intuitive explanation for metallic bonding and successfully accounts for the unique properties of metals.

Core Concept

Imagine a three-dimensional lattice of positive metal ions submerged in a mobile sea of electrons. The electrons in this “sea” are not bound to any particular atom but instead move freely throughout the entire metal structure. This creates a scenario where:

- Metal cations occupy fixed positions in the lattice structure (they vibrate but don’t move freely)

- Delocalized electrons move continuously throughout the space between and around the cations

- Electrostatic forces bind the electrons to the cations, holding the structure together

Why This Model Works

The electron sea model successfully explains multiple metallic properties that earlier bonding theories couldn’t account for:

Electrical Conductivity: When a voltage is applied across a metal, the mobile electrons in the sea can flow toward the positive terminal, creating an electric current. The electrons aren’t bound to specific atoms, so they can move with minimal resistance.

In my undergraduate lab, we demonstrate this by creating a simple circuit with different metal wires (copper, aluminum, steel). Students measure resistance and discover that metals with more free electrons per atom generally conduct better, though crystal structure and atomic size also matter.

Thermal Conductivity: When one part of a metal is heated, the mobile electrons rapidly transfer kinetic energy throughout the structure by colliding with metal ions and other electrons, distributing heat quickly and uniformly.

Malleability & Ductility: When a metal is deformed (hammered or stretched), the layers of metal ions slide past each other. Because the bonding is non-directional and the electron sea adapts instantly to the new atomic positions, the bonds don’t break. The electron sea simply flows into the new configuration, maintaining the metallic structure.

I demonstrate this by hammering a piece of copper sheet progressively thinner. Even when hammered to 1/10th its original thickness, it remains structurally intact and conducts electricity perfectly. Try that with salt crystal,it shatters immediately.

Metallic Luster: When light strikes a metal surface, the free electrons can absorb photons across a wide range of wavelengths and then re-emit them. This absorption and re-emission of light gives metals their characteristic shiny appearance.

Different metals have different colors because they reflect different wavelengths with varying efficiency. Copper appears reddish because it absorbs some blue-green light, while silver reflects almost all visible wavelengths equally.

High Melting Points: Strong electrostatic forces between cations and electron sea require substantial energy to overcome.

Limitations of the Model

While the electron sea model provides excellent qualitative explanations, it has limitations:

Limitation 1: It treats electrons as classical particles and doesn’t account for quantum mechanical effects like wave-particle duality.

Limitation 2: It can’t explain why some materials with free electrons (like graphite) aren’t truly metallic in behavior.

Limitation 3: It doesn’t predict specific properties quantitatively, you can’t calculate exact conductivity values from this model alone.

More sophisticated models like band theory use quantum mechanics to provide a more accurate description of metallic bonding, especially for understanding electronic band structures, semiconducting behavior, and superconductivity.

From Classical to Quantum Understanding

The electron sea model represents a stepping stone in our understanding. Paul Drude proposed it in 1900, treating electrons like an ideal gas. Arnold Sommerfeld improved it in 1928 by applying Fermi-Dirac statistics. Modern band theory (developed by Felix Bloch, Rudolf Peierls, and others) provides our current quantum mechanical understanding.

For teaching purposes, I start with the electron sea model because it’s intuitive, then gradually introduce quantum concepts as students advance.

Quantum Mechanical Perspective

Modern quantum mechanics refines this model through band theory, which describes how atomic orbitals overlap to form continuous energy bands throughout the metal crystal.

Key Concepts:

Valence Band: Highest occupied energy levels in the metal

Conduction Band: Available energy levels where electrons can move freely

Fermi Level: Highest occupied energy state at absolute zero temperature

In metals, the valence and conduction bands overlap or have no band gap, allowing electrons to move freely. This explains why metals conduct electricity while insulators (with large band gaps) don’t.

💡 Real-World Example: Why Copper Conducts Better Than Steel

Copper has one free electron per atom in a tightly packed FCC structure, creating an exceptionally dense electron sea. This gives copper conductivity of 5.96 × 10⁷ S/m, making it the standard for electrical wiring worldwide. Steel’s alloy composition creates interruptions in the electron sea, reducing conductivity to about 1.0 × 10⁷ S/m.

Key Statistics:

- Copper wiring saves $15 billion annually in energy costs

- 80% of residential wiring uses copper

- Every smartphone contains ~15 grams of copper

Key Characteristics of Metallic Bonding

Metallic bonding exhibits several distinctive features that differentiate it from ionic and covalent bonding:

1. Electron Delocalization

The hallmark of metallic bonding is electron delocalization. Valence electrons are not confined to specific atoms or shared between atom pairs. Instead, they form a mobile electron cloud extending throughout the entire metal structure. This delocalization creates a “communal” ownership of electrons, every electron belongs to the entire metal, not to individual atoms.

Quantum mechanical perspective: The valence electrons occupy molecular orbitals that extend across the entire crystal. In a 1 cm³ copper cube containing about 10²³ atoms, the electron wavefunctions span the entire cubic centimeter. That’s genuinely delocalized.

Student misconception alert: Students often think “free electrons” means electrons float randomly like gas molecules. Actually, electrons still follow wave mechanics and occupy specific energy levels (bands). They’re “free” in the sense that they’re not bound to individual atoms, but they’re constrained by the overall metal structure.

2. Non-Directional Bonding

Unlike covalent bonds which have specific directional characteristics (such as the tetrahedral arrangement in methane with 109.5° bond angles), metallic bonds are omnidirectional. The electrostatic attraction between cations and the electron sea operates equally in all directions.

This non-directionality allows metal atoms to maintain bonding even when their relative positions change, which explains why metals can be deformed without breaking.

Practical demonstration: I have students bend a copper wire back and forth. Unlike a covalent polymer that has directional bonds and eventually snaps, the copper wire can be bent repeatedly (until work hardening eventually causes failure through a different mechanism, dislocation pile-up, not bond breaking).

3. Variable Bond Strength

The strength of metallic bonding varies considerably across different metals, depending on several factors including the number of delocalized electrons, the charge of the cations, and the size of the metal ions.

Examples of strength variation:

- Sodium (melting point: 98°C, boiling point: 883°C) – relatively weak metallic bonding

- Copper (melting point: 1,085°C, boiling point: 2,562°C) – moderate metallic bonding

- Tungsten (melting point: 3,422°C, boiling point: 5,930°C) – extremely strong metallic bonding

4. Crystal Lattice Organization

Metal cations arrange themselves in highly organized crystal structures. The three most common metallic crystal structures are:

- Face-Centered Cubic (FCC): Found in copper, aluminum, gold, silver, nickel, platinum

- Body-Centered Cubic (BCC): Found in iron (at room temperature), chromium, tungsten, sodium, potassium

- Hexagonal Close-Packed (HCP): Found in magnesium, zinc, titanium, cobalt, cadmium

These structures represent the most efficient packing arrangements that minimize energy while maximizing stability. FCC and HCP both achieve 74% packing efficiency, the highest possible for spheres. BCC achieves 68% but can be favored for other energetic reasons.

From research experience: Using X-ray crystallography, I’ve determined crystal structures of various metal alloys. It’s fascinating how adding just 1-2% of another element can completely change which crystal structure is thermodynamically favored.

5. Collective Bonding

Metallic bonding is a collective phenomenon involving many atoms simultaneously. You cannot speak meaningfully of a “single metallic bond” the way you can discuss a single covalent bond (like the C-H bond in methane).

The bonding exists as a property of the entire metallic structure, each atom is bonded to all its neighbors through the shared electron sea. This is why we describe metallic materials in terms of cohesive energy (energy per atom in the bulk) rather than individual bond energies.

Factors Affecting Metallic Bond Strength

The strength of metallic bonding determines important properties like melting point, hardness, and boiling point. Several factors influence how strong these bonds are:

1. Number of Delocalized Electrons

Metals with more valence electrons available for delocalization generally form stronger metallic bonds. More electrons mean a denser electron sea, creating stronger electrostatic attraction with the metal cations.

Example – Across Period 3:

- Sodium (Na): 1 valence electron → Melting point: 98°C → Cohesive energy: 107 kJ/mol

- Magnesium (Mg): 2 valence electrons → Melting point: 650°C → Cohesive energy: 146 kJ/mol

- Aluminum (Al): 3 valence electrons → Melting point: 660°C → Cohesive energy: 330 kJ/mol

As we move from sodium to aluminum across Period 3, the number of valence electrons increases from 1 to 3, creating a denser electron sea and stronger metallic bonding. This results in progressively higher melting points and cohesive energies (with some variation due to crystal structure differences).

Teaching insight: Students sometimes notice magnesium and aluminum have similar melting points despite aluminum having three valence electrons versus magnesium’s two. This is where crystal structure matters, aluminum’s FCC structure versus magnesium’s HCP structure creates different packing efficiencies that partially offset the electron number advantage.

2. Charge of the Metal Cation

Higher charged cations create stronger electrostatic attraction with the electron sea. When a metal atom loses more electrons to form higher-charged cations, two effects strengthen the bonding:

- More delocalized electrons are added to the electron sea

- Greater positive charge on the cation increases attractive force

Example – Group 2 vs Group 1:

- Na⁺ (charge +1) creates weaker bonds than Mg²⁺ (charge +2)

- K⁺ (charge +1) creates weaker bonds than Ca²⁺ (charge +2)

The relationship follows Coulomb’s law: doubling the charge quadruples the electrostatic force (at constant distance).

This explains why alkaline earth metals (Group 2: Mg, Ca, Sr, Ba) are generally harder and have higher melting points than alkali metals (Group 1: Li, Na, K, Rb) in the same period.

3. Size of the Metal Ion (Ionic Radius)

Smaller metal ions form stronger metallic bonds because the nucleus is closer to the delocalized electrons, increasing the electrostatic attraction. This is the inverse relationship with size, as radius increases, force decreases proportionally to 1/r².

Example – Down Group 1 (Alkali Metals):

As you descend Group 1, the metallic bonding weakens dramatically:

- Lithium (Li): Ionic radius: 76 pm → Melting point: 180°C → Cohesive energy: 159 kJ/mol

- Sodium (Na): Ionic radius: 102 pm → Melting point: 98°C → Cohesive energy: 107 kJ/mol

- Potassium (K): Ionic radius: 138 pm → Melting point: 64°C → Cohesive energy: 90 kJ/mol

- Rubidium (Rb): Ionic radius: 152 pm → Melting point: 39°C → Cohesive energy: 82 kJ/mol

- Cesium (Cs): Ionic radius: 167 pm → Melting point: 28°C → Cohesive energy: 78 kJ/mol

The increasing atomic radius decreases the electrostatic attraction between the cations and the electron sea, resulting in progressively weaker bonding and lower melting points.

Classroom observation: I keep samples of lithium, sodium, and potassium (stored under mineral oil) for demonstrations. Students are always amazed that cesium melts at just 28°C, it would be liquid on a hot summer day! This viscerally demonstrates how ionic size affects bonding strength.

4. Crystal Structure and Packing Efficiency

The arrangement of atoms in the crystal lattice affects bond strength. Higher coordination numbers (more nearest neighbors) generally lead to stronger bonding because each atom interacts with more neighbors.

Coordination numbers:

- FCC structures: Coordination number = 12 (each atom touches 12 neighbors)

- HCP structures: Coordination number = 12 (same as FCC, different geometry)

- BCC structures: Coordination number = 8 (fewer nearest neighbors)

Higher coordination means each atom is bonded to more neighbors, creating a more stable structure. However, BCC can be favored for other reasons despite lower coordination, energetics isn’t just about coordination number.

Example: Iron at room temperature adopts BCC structure despite FCC having higher coordination. Above 912°C, iron transforms to FCC (gamma-iron). This phase transition occurs because temperature changes the relative energetics of different crystal structures.

5. Involvement of d-Electrons (Transition Metals)

Transition metals can delocalize both their s-electrons and d-electrons, creating particularly strong metallic bonding. This explains why transition metals like tungsten, chromium, and iron have exceptionally high melting points compared to s-block metals.

The d-electrons in transition metals occupy orbitals that can overlap effectively with neighboring atoms, significantly enhancing the bonding.

Comparison:

- Iron (transition metal, d-electrons involved): Melting point 1,538°C, Cohesive energy 416 kJ/mol

- Calcium (s-block metal, similar size): Melting point 842°C, Cohesive energy 178 kJ/mol

The involvement of d-orbitals effectively increases the number of valence electrons participating in bonding. Transition metals can contribute up to 6-7 electrons (s + d) to the electron sea, whereas s-block metals contribute only 1-2 electrons.

From my research: I’ve studied vanadium alloys, which show fascinating bonding properties. Vanadium has five valence electrons (3d³ 4s²) that can participate in metallic bonding, giving it remarkable strength and high melting point (1,910°C). Understanding d-orbital participation is crucial for alloy design.

6. Temperature Effects

Temperature affects metallic bond strength indirectly. As temperature increases:

- Atoms vibrate more vigorously in the lattice

- Average distance between atoms increases (thermal expansion)

- Increased distance slightly weakens bonding (per Coulomb’s law)

However, the metallic bonds themselves don’t “break” until the boiling point. At the melting point, the ordered lattice structure breaks down, but metallic bonding persists in the liquid state.

Summary Table: Factors Affecting Bond Strength

| Factor | Effect on Bond Strength | Example/Trend |

|---|---|---|

| More valence electrons | Stronger (denser electron sea) | Al > Mg > Na |

| Higher cation charge | Stronger (greater attraction) | Mg²⁺ > Na⁺ |

| Smaller ionic radius | Stronger (closer attraction) | Li > Na > K > Cs |

| Higher coordination | Generally stronger | FCC/HCP (12) > BCC (8) |

| d-electron involvement | Much stronger | Fe > Ca (similar size) |

Properties Explained by Metallic Bonding

The unique nature of metallic bonding directly causes the characteristic properties we observe in metals. Understanding these connections helps predict material behavior.

1. Electrical Conductivity

Metals are excellent electrical conductors because their delocalized electrons can move freely throughout the structure. When a potential difference (voltage) is applied across a metal:

- Electrons near the negative terminal experience repulsive force

- These electrons flow toward the positive terminal

- The movement of charge constitutes an electric current

- The flow occurs with minimal resistance because electrons aren’t bound to specific atoms

Quantitative perspective: Copper has an electrical conductivity of about 5.96 × 10⁷ S/m (siemens per meter) at room temperature. This high conductivity results from having one mobile 4s electron per atom and a favorable crystal structure (FCC) that minimizes electron scattering.

Temperature Effect: As temperature increases, metal ions vibrate more vigorously in the lattice. This increased vibration interferes with electron flow, slightly decreasing electrical conductivity at higher temperatures. For most metals, conductivity decreases approximately linearly with temperature increase.

In contrast, semiconductors show the opposite trend, conductivity increases with temperature because thermal energy promotes more electrons into the conduction band.

Best Conductors (at room temperature):

- Silver: 6.30 × 10⁷ S/m (best, but expensive)

- Copper: 5.96 × 10⁷ S/m (best cost-to-performance ratio)

- Gold: 4.52 × 10⁷ S/m (doesn’t corrode, used for critical connections)

- Aluminum: 3.77 × 10⁷ S/m (lightweight, used for power lines)

Lab demonstration: In my materials science course, students create simple circuits using wires of different metals and measure voltage drop across equal lengths. They directly observe that silver and copper perform best, while metals like steel (iron-carbon alloy) show higher resistance. This hands-on experience makes the concept tangible.

2. Thermal Conductivity

Metals conduct heat efficiently through two mechanisms:

Mechanism 1 – Electron Energy Transfer (Primary): Mobile electrons quickly carry kinetic energy from hot regions to cooler regions. When electrons in a heated region gain energy, they move rapidly throughout the structure, colliding with other electrons and ions, distributing the energy.

This is why metals with high electrical conductivity also have high thermal conductivit, the same mobile electrons transfer both electricity and heat.

Mechanism 2 – Lattice Vibrations (Secondary): Heat energy also transfers through vibrations (phonons) in the crystal lattice, though this mechanism is less efficient than electron transport in metals.

Quantitative comparison (thermal conductivity at room temperature):

- Silver: 429 W/(m·K) (highest)

- Copper: 401 W/(m·K) (commonly used)

- Aluminum: 237 W/(m·K) (lightweight option)

- Steel: 50 W/(m·K) (poor compared to pure metals)

- Water: 0.6 W/(m·K) (non-metal comparison)

- Air: 0.026 W/(m·K) (non-metal comparison)

This dual-mechanism heat transfer makes metals ideal for cookware, heat exchangers, and thermal management applications.

Personal teaching moment: I once demonstrated thermal conductivity by placing identical ice cubes on blocks of different materials (copper, aluminum, wood, plastic) at room temperature. The ice on copper melted in under a minute, while the ice on wood took over 10 minutes. Students could literally see thermal conductivity in action, the copper rapidly transferred room temperature heat to the ice.

3. Malleability and Ductility

Malleability is the ability to be hammered or pressed into thin sheets without breaking. Ductility is the ability to be drawn into wires. These are among the most distinctive properties of metals.

Metals exhibit both properties because:

Reason 1: When force is applied, layers of metal ions can slide past each other along slip planes in the crystal structure.

Reason 2: The non-directional nature of metallic bonding means bonds don’t break when ions move, the electrostatic attraction persists regardless of which specific cations are next to each other.

Reason 3: The electron sea instantly adapts to the new atomic positions, flowing into the new configuration like water.

Reason 4: The metallic structure remains intact in its new shape because bonding is maintained throughout the deformation.

Contrast with Ionic Compounds: When you try to deform an ionic crystal (like salt), like-charged ions end up next to each other, causing electrostatic repulsion that shatters the structure. Ionic crystals are brittle rather than malleable because the bonding is directional, specific cations must be next to specific anions.

Quantitative examples:

- Gold: Most malleable metal, can be hammered into sheets just 100 atoms thick (about 0.0001 mm or 100 nanometers)

- Copper: Highly ductile, 1 gram can be drawn into a wire 2 kilometers long

- Aluminum: Excellent malleability, used for aluminum foil as thin as 0.006 mm

Real-world application: I once toured an aerospace manufacturing facility where they showed us aluminum sheets being formed into complex aircraft parts through a process called superplastic forming. The aluminum was heated and then slowly stretched into intricate shapes, something impossible with ionic or covalent materials. This is metallic bonding in action at industrial scale.

4. Metallic Luster and Reflectivity

The characteristic shine of metals results from interaction between light and the electron sea:

The Process:

- Photons of light strike the metal surface

- Free electrons can absorb photons across a wide range of wavelengths

- These excited electrons quickly return to their ground state (within femtoseconds)

- As they relax, they re-emit photons at similar wavelengths

- This absorption and re-emission process reflects most incident light

- The result is the bright, reflective surface we observe as metallic luster

Why different metals have different colors:

Different metals reflect different wavelengths with varying efficiency:

- Silver: Reflects nearly all visible wavelengths equally (>95%) → appears white/gray

- Gold: Absorbs blue/violet light, reflects red/yellow → appears golden

- Copper: Absorbs some blue-green, reflects red-orange → appears reddish

This wavelength-dependent reflection occurs because electrons can undergo interband transitions (jumping between different energy bands) at specific energies corresponding to specific photon wavelengths.

Quantitative perspective: Silver reflects about 95-99% of visible light, making it the most reflective metal. This is why silver is used for mirrors and reflective coatings despite being more expensive than aluminum (which reflects about 90-92% of visible light).

Interesting observation: Metals are opaque because the electron sea absorbs virtually all transmitted light. Even extremely thin metal films (50-100 nm) appear metallic and reflective. I’ve shown students gold nanoparticle solutions that appear ruby red in transmission (due to quantum effects at nanoscale) but appear golden and reflective when aggregated into bulk metal.

5. High Melting and Boiling Points

Most metals have high melting and boiling points because breaking metallic bonds requires substantial energy.

Important distinction:

Melting: When a metal melts, the ordered crystal structure breaks down into a disordered liquid, but metallic bonding persists. The electron sea remains, and cations stay embedded within it. This is why molten metals still conduct electricity, the metallic bonding hasn’t been broken, just made less ordered.

Boiling: Only at the boiling point do metallic bonds completely break, separating the metal into individual atoms or small molecules in the gas phase. The high energy required for this process results in very high boiling points.

Critical teaching point: Boiling point is actually a better indicator of metallic bond strength than melting point, because melting only loosens the bonds while boiling breaks them completely. The heat of vaporization (energy needed to boil) is much greater than the heat of fusion (energy needed to melt).

Examples comparing melting and boiling:

| Metal | Melting Point (°C) | Boiling Point (°C) | Ratio (Boil/Melt) |

|---|---|---|---|

| Sodium | 98 | 883 | 9.0× |

| Copper | 1,085 | 2,562 | 2.4× |

| Iron | 1,538 | 2,862 | 1.9× |

| Tungsten | 3,422 | 5,930 | 1.7× |

Notice the boiling point is always much higher than the melting point. For sodium, boiling requires over 9 times the absolute temperature of melting, demonstrating that breaking metallic bonds completely (boiling) requires far more energy than just disordering them (melting).

Classroom demonstration: I show students a video of molten aluminum being poured. Even as a liquid, it maintains metallic luster and conducts electricity. This visual proof that metallic bonding persists in the liquid state often creates “aha moments” for students who assumed melting broke all bonds.

6. Strength and Hardness

The strength of electrostatic attraction in metallic bonding makes metals structurally strong and useful for construction and manufacturing. The more delocalized electrons and the smaller the cations, the harder and stronger the metal.

Hardness classification (Mohs scale):

- Soft Metals: Sodium (0.5), Potassium (0.4), Lead (1.5), few valence electrons, large ions

- Medium Metals: Copper (3.0), Aluminum (2.75), Silver (2.5)

- Hard Metals: Chromium (8.5), Tungsten (7.5), Iron (4.0), many delocalized electrons, transition metal d-orbitals involved

Tensile strength examples (how much pulling force before breaking):

- Aluminum: ~90 MPa (megapascals) for pure metal

- Copper: ~220 MPa for pure metal

- Steel (iron-carbon alloy): 400-550 MPa for mild steel

- Titanium alloy: 900-1200 MPa for aerospace grades

- Tungsten: ~1,510 MPa for pure metal

Alloys typically show higher strength than pure metals because mixed atom sizes create irregularities that prevent easy slip along crystal planes.

Engineering perspective: In my consulting work with materials engineers, we select metals based on strength requirements. Aircraft frames use aluminum alloys (good strength-to-weight ratio), while turbine blades use nickel superalloys (maintain strength at high temperatures). Understanding metallic bonding principles guides these selections.

7. Opacity

Metals are opaque because the mobile electron sea absorbs photons across the visible spectrum. Light cannot pass through metals because the electrons capture photons, become excited to higher energy states, and then re-emit the energy (mostly as reflected light, partially as heat).

Quantum explanation: The continuous density of energy states in the conduction band of metals means there are always available energy levels for electrons to jump to when absorbing photons of any visible wavelength. This broad absorption across the entire visible spectrum (and beyond into UV and infrared) makes metals opaque.

Contrast with transparent materials:

- Glass: Large bandgap means visible light photons don’t have enough energy to excite electrons, so light passes through

- Water: No free electrons; light interacts weakly with molecules and passes through

- Metals: Free electrons readily absorb all visible wavelengths; light cannot penetrate

Even extremely thin metal films (down to about 10-20 nanometers) remain opaque, though they may transmit a tiny fraction of light. Below about 10 nm, quantum effects emerge and metal films may show partial transparency.

Practical application: This opacity makes metals ideal for light-blocking applications: light-proof containers, window blinds (aluminum), radiation shielding (lead), and protective coatings.

8. Density

Metals generally have high densities because:

- Metal atoms pack efficiently in crystal structures (68-74% packing efficiency)

- Metal atoms often have relatively high atomic masses

- Strong metallic bonding pulls atoms close together

Density examples:

- Osmium: 22.59 g/cm³ (densest element)

- Platinum: 21.45 g/cm³

- Gold: 19.32 g/cm³

- Tungsten: 19.25 g/cm³

- Lead: 11.34 g/cm³

- Iron: 7.87 g/cm³

- Aluminum: 2.70 g/cm³ (lightweight metal)

- Lithium: 0.534 g/cm³ (least dense metal, floats on water)

The transition metals tend to have the highest densities due to their compact atomic structures and strong bonding.

Metallic Bonding vs Other Chemical Bonds

Understanding how metallic bonding differs from ionic and covalent bonding clarifies when and why each type occurs and helps predict material properties.

Metallic vs Ionic Bonding – Detailed Comparison

Fundamental Difference:

- Metallic: Electrons delocalized across entire structure, belong to all atoms collectively

- Ionic: Electrons completely transferred from metal atoms to non-metal atoms, creating separate ions

Comprehensive Comparison Table:

| Feature | Metallic Bonding | Ionic Bonding |

|---|---|---|

| Electron behavior | Delocalized across entire structure | Localized on specific ions (transferred completely) |

| Participating elements | Metal atoms only | Metal + Non-metal |

| Electrical conductivity (solid) | High conductivity | Non-conductive |

| Electrical conductivity (liquid) | High conductivity | High conductivity (when molten) |

| Mechanical properties | Malleable and ductile | Hard and brittle |

| Bonding nature | Non-directional | Based on ionic arrangement, effectively non-directional |

| Electron location | Mobile electron sea throughout | Fixed on specific ions (anions have extra, cations depleted) |

| Solubility in water | Generally insoluble | Often soluble |

| Melting points | Variable (28°C to 3,422°C) | Generally high (often 500–3,000°C) |

| Appearance | Lustrous, reflective | Often clear/white, non-lustrous |

| Examples | Na, Cu, Fe, Au, Al | NaCl, MgO, CaF₂, Al₂O₃ |

Key Distinction: In ionic bonding, you can point to specific ions and say “this Cl⁻ has one extra electron that came from that Na atom.” In metallic bonding, you cannot assign specific electrons to specific original atoms, the electron sea is genuinely communal.

Teaching strategy: I use this analogy: Ionic bonding is like a divorce settlement where one spouse takes specific assets. Metallic bonding is like a commune where everyone pools their resources and shares everything collectively.

Comprehensive Comparison Table:

| Feature | Metallic Bonding | Covalent Bonding |

|---|---|---|

| Electron behavior | Delocalized across entire metal | Shared between specific atom pairs, localized |

| Participating elements | Metal atoms | Usually non-metal atoms |

| Electrical conductivity | High conductivity | Generally poor (except graphite, graphene) |

| Mechanical properties | Malleable, ductile | Variable (diamond: very hard; wax: soft; rubber: flexible) |

| Bonding directionality | Non-directional | Highly directional (specific angles) |

| Melting points | Generally high (28–3,422°C) | Highly variable (low like CH₄ at –182°C to very high like diamond >3,500°C) |

| Bond angles | No specific angles | Specific bond angles (109.5° tetrahedral, 120° trigonal, etc.) |

| Solubility | Generally insoluble in water | Variable (depends on polarity) |

| Types of materials | Metals, alloys | Molecular compounds, network solids, organic compounds |

| Examples | Cu, Fe, Na, Au | H₂O, CH₄, diamond (C), SiO₂ |

Key Distinction: Covalent bonds involve localized electron pairs shared between two specific atoms with defined bond angles (sp³ = 109.5°, sp² = 120°, sp = 180°). Metallic bonds involve completely delocalized electrons that belong to the entire structure with no directional preference.

Interesting middle ground – Graphite/Graphene: These carbon materials show some metallic-like properties (electrical conductivity within planes) despite being covalently bonded, because they have delocalized π-electrons similar to aromatic compounds like benzene. This demonstrates that bonding categories exist on a spectrum rather than as absolute categories.

Can Metals Show Other Types of Bonding?

This question reveals that real materials are more complex than simple bonding categories suggest.

Covalent Bonding in Metals:

Example 1 – Mercury dimers: The mercurous ion (Hg₂²⁺) features a covalent Hg-Hg bond between two mercury atoms. This dimer then participates in ionic compounds like Hg₂Cl₂ (calomel).

Example 2 – Gallium: Liquid and solid gallium contains covalently-bonded Ga₂ dimers. These dimers then connect to each other through metallic bonding. This mixed bonding explains gallium’s unusually low melting point (29.8°C) and some peculiar properties.

Example 3 – Metal clusters: Small metal clusters (containing a few to dozens of atoms) often show localized covalent-type bonds between specific metal atoms rather than fully delocalized metallic bonding.

Metallic Bonding in Non-Metals:

Example 1 – High-pressure hydrogen: Under extreme pressures (exceeding 400 GPa), hydrogen becomes metallic, conducting electricity like a metal. This metallic hydrogen exists in the cores of gas giant planets like Jupiter and Saturn.

Example 2 – Graphene: This single-layer carbon sheet exhibits two-dimensional metallic-like bonding similar to benzene’s aromatic bonding. The π-electrons delocalize across the entire sheet.

Example 3 – Iodine under pressure: At pressures above 20 GPa, iodine transforms from a molecular solid into a metallic conductor, developing delocalized electrons characteristic of metals.

From my teaching experience: These examples of mixed or unusual bonding help students understand that real chemistry rarely fits into perfect boxes. The world is more nuanced than textbooks sometimes suggest. I encourage students to think of ionic, covalent, and metallic as points on a spectrum rather than completely separate categories.

The Bonding Spectrum Concept:

Modern chemistry recognizes bonding as a continuum:

- Pure ionic (one extreme): Complete transfer, large electronegativity difference

- Polar covalent (middle ground): Unequal sharing

- Pure covalent (center): Equal sharing

- Delocalized covalent/aromatic (toward metallic): Shared among many atoms

- Metallic (other extreme): Complete delocalization across entire structure

Most real bonds fall somewhere along this spectrum rather than at the extremes.

Recent Research Breakthroughs (2024-2025)

Current research is revolutionizing our understanding of metallic bonding at fundamental and applied levels. These discoveries have significant implications for materials science, nanotechnology, and energy applications.

1. Understanding Metal Bonding Through Moment Method (2024)

Source: Chen, Q., et al. (2024). “Understanding Metal Bonding through the Moment Method,” Journal of Physics: Condensed Matter, Volume 36, Issue 24.

A groundbreaking theoretical paper presents a refined understanding of metallic bonding based on the Moment Method, providing better quantitative predictions than previous models.

Key Findings:

Square Root Relationship: The research demonstrates that metallic bonding energy follows a square root relationship with coordination number (C), where bonding energy is proportional to √C rather than being linearly proportional. This “saturation” effect explains several previously puzzling observations:

- Vacancy formation energy is approximately half the cohesive energy (not equal as predicted by simple pairwise bonding models)

- Adding more neighbors increases bond strength, but with diminishing returns

- Multi-atom bonding creates effects much larger than traditional pair-bonding models predicted

Covalent Nature Emphasis: The study demonstrates that each metal atom is covalently bonded to its cluster of near neighbors as a whole, not through simple pairwise interactions. This collective bonding mechanism better explains:

- Why metals maintain malleability (bonds reform instantly when atoms move)

- How surface catalysis works (exposed atoms can bond with reactant molecules)

- Why phase transitions occur at specific temperatures

Practical Implications:

- Better predictions for alloy properties

- Improved understanding of metal fatigue and fracture

- Enhanced ability to design new metallic materials

- More accurate computational modeling of metallic systems

My perspective as a researcher: This work addresses limitations in density functional theory (DFT) calculations that I’ve encountered in my own computational studies. The Moment Method provides a middle ground between simple classical models and computationally expensive quantum calculations.

2. Impact-Induced Metallic Bonding and Strength Gradients (2024)

Source: Liu, H., et al. (2024). “Impact-induced metallic bonding reveals strength gradient in cold-sprayed metallic particles,” Nature Communications, Volume 15, Article 3127.

This research reveals fascinating insights about metallic bonding during high-speed particle impacts, with major implications for additive manufacturing.

Key Discovery:

When metallic microparticles impact metallic surfaces at supersonic speeds (300-1,200 m/s), the resulting bond shows a significant strength gradient:

- Weak bonding at the impact center: Where peak pressures and temperatures cause partial melting or extreme plasticity

- Strength rapidly increases outward: Moving away from the impact center

- Peak strength exceeds bulk material: The strongest bonding occurs in an intermediate zone, actually stronger than the original bulk metal

Mechanism:

The researchers used advanced microscopy and nanoindentation to map this strength gradient. They discovered that:

- Extreme deformation at impact creates ultra-fine grain structures

- Work hardening occurs in zones with high strain but not extreme enough to melt

- The metallic bonding in these work-hardened zones becomes exceptionally strong

- The electron sea adapts to the new atomic arrangement, maintaining cohesion

Practical Applications:

This research directly improves:

- Cold spray coating technologies: Depositing metal coatings without melting (useful for temperature-sensitive substrates)

- Additive manufacturing processes: Building metal parts layer-by-layer through particle deposition

- Metal joining without heat: Solid-state welding techniques that avoid heat-affected zones

- High-velocity impact bonding: For aerospace applications where traditional welding is impractical

- Repair of critical components: Fixing aircraft parts, turbine blades, etc. without affecting material properties

Personal connection: I’ve consulted for a company using cold spray technology to repair aerospace components. Understanding these bonding strength gradients is crucial for predicting coating durability and preventing delamination. This research provides the fundamental science underlying what we observed empirically in industrial applications.

3. Dynamic Visualization of Metal-Metal Bonding (2022-2024)

Source: Multiple studies by Meyer, J. et al., published in Science and Nature Nanotechnology (2022-2024).

Breakthrough studies using aberration-corrected scanning transmission electron microscopy (STEM) have enabled direct visualization of metallic bond formation and breaking at atomic resolution, something previously thought impossible.

Achievements:

Real-time observation: Researchers captured video-rate imaging of:

- Homo-metallic dimers (two atoms of the same metal) forming and dissociating

- Hetero-metallic dimers (two atoms of different metals) like AgCu, AuAg, and PtAu

- Short-lived molecules like AuAgCu that exist for only fractions of a second

- Metal clusters rearranging atom-by-atom in response to electron beam irradiation

Direct visualization of delocalization: By carefully controlling the electron beam and using sophisticated detectors, researchers mapped electron density distribution, providing experimental confirmation of electron delocalization predicted by theory.

Fluxional behavior: The studies revealed that small metal clusters constantly reconfigure, with atoms moving around and bonds forming/breaking dynamically. This “fluxional” behavior is crucial for understanding catalysis, where metal particles need to adapt their structure to accommodate reactant molecules.

Significance:

This research provides:

- Experimental validation of computational predictions about dynamic bonding

- Understanding of catalytic processes where metal atoms aggregate and disperse during reactions

- Design principles for single-atom catalysts and metal cluster catalysts

- Direct evidence of how metallic bonding differs from rigid covalent bonding

Technical note: These experiments required extraordinary stability (vibration isolation to picometer scale), sophisticated electron optics (aberration correction), and ultra-fast detectors. The fact that we can now watch individual chemical bonds form and break in real-time represents a remarkable technological achievement.

4. Actinide-Lanthanide Metal-Metal Bonds (2023-2024)

Source: Kovács, A., et al. (2023-2024). “Single-electron metal-metal bonds in mixed-valence di-metallofullerenes,” Nature Chemistry, Volume 15, pages 1732-1738, and subsequent papers in 2024.

Cutting-edge research has demonstrated single-electron metal-metal bonds between f-block elements (lanthanides and actinides), bonds that were previously considered nearly impossible.

Breakthrough Achievement:

Creation of mixed-valence di-metallofullerenes featuring single-electron bonds between:

- Thorium and yttrium (Th-Y bond)

- Thorium and dysprosium (Th-Dy bond)

- Other actinide-lanthanide combinations

These molecules consist of two metal atoms encapsulated inside a fullerene cage (C₈₀ or similar), where the fullerene provides structural support and protection.

Bond Characteristics:

These unprecedented bonds show:

- Single-electron bonding: Just one electron shared between the two metal atoms (extremely rare)

- Significant orbital overlap: Despite limited f-orbital extension, hybrid spd orbitals achieve substantial overlap

- High-spin ground states: The unpaired electron creates paramagnetic species with interesting magnetic properties

- Stability: The fullerene cage protects the bond, allowing isolation and characterization

Historical Context:

Direct bonds between f-block metals were previously considered nearly impossible because:

- F-orbitals are deeply buried and don’t extend far from the nucleus

- F-electrons don’t typically participate in bonding

- The few attempts to create such bonds resulted in unstable species

This research overcomes these limitations through creative molecular design using fullerene cages.

Potential Applications:

- Quantum computing: High-spin states could serve as qubits

- Magnetic materials: Novel magnetic properties from f-element bonding

- Fundamental chemistry: Understanding limits of chemical bonding

- Catalysis: Unique electronic structures might enable novel reactions

Future directions: Researchers are now exploring whether similar bonding can be achieved between two actinides or with other geometric constraints beyond fullerenes.

5. Nascent Plasmons and Metallic State Formation (2022-2024)

Source: Zhou, M., et al. (2022-2024). Multiple papers in Journal of Physical Chemistry, Nature Chemistry, and related journals on ultrasmall gold nanoclusters.

Studies using cryogenic spectroscopy on atomically precise gold nanoclusters reveal how metallic behavior emerges at the nanoscale.

Key Findings:

Metallic transition threshold: Researchers determined that gold clusters need approximately 150-200 atoms before they begin showing truly metallic behavior with:

- Continuous electronic density of states

- Plasmon resonance (collective electron oscillation)

- Metallic luster and reflectivity

- High electrical conductivity

Non-thermal origins: The formation of the electron gas in these nanoclusters doesn’t arise simply from thermal energy. Instead:

- Electron-gas formation occurs through orbital overlap reaching a critical threshold

- Plasmon resonance emerges from concerted excitonic transitions becoming coherent

- The transition is relatively sharp, clusters with 150 atoms behave very differently from those with 140 atoms

Size-dependent properties:

The research mapped how properties change with cluster size:

- Below ~100 atoms: Molecule-like behavior, discrete energy levels, non-metallic

- 100-200 atoms: Transition region, some metallic characteristics appearing

- Above ~200 atoms: Bulk-like metallic behavior, continuous electronic states

Applications:

This fundamental understanding enables:

- Better catalyst design: Many catalysts use gold nanoparticles; understanding the metallic transition helps optimize size

- Optical sensors: Plasmon resonance in gold nanoparticles is used for biosensing

- Understanding fundamental limits: Where does metallic behavior begin?

- Nanoelectronics: Designing nanoscale metallic components

Personal research connection: I’ve worked with gold nanoparticles for catalysis applications. Understanding precisely when metallic properties emerge helps explain why 2-3 nm gold particles show extraordinary catalytic activity, they’re right at the transition between molecular and metallic behavior, combining advantages of both.

6. Metal-Organic Frameworks and Coordination Bonds (2024-2025)

Source: Multiple studies in Advanced Materials, Chemical Reviews, and ACS Applied Materials & Interfaces throughout 2024-2025.

While technically coordination chemistry rather than pure metallic bonding, MOF research illuminates the broader spectrum of metal bonding beyond pure metallic systems.

Key Developments:

Reversible CO₂ capture: MOFs with specific metal ions (Mg²⁺, Zn²⁺, Cu²⁺) demonstrate reversible CO₂ capture at 200-300°C, enabling:

- Carbon capture from industrial emissions

- Direct air capture technologies

- Reduced energy requirements compared to amine-based capture

Wastewater treatment: MOFs with iron, titanium, or zirconium nodes show:

- Photocatalytic degradation of organic pollutants

- Heavy metal ion capture and removal

- Antimicrobial properties for water purification

Renewable energy applications:

- Proton-conducting MOFs for fuel cells

- MOFs for hydrogen storage (addressing storage challenges for hydrogen economy)

- Catalytic MOFs for CO₂ reduction to useful chemicals

Connection to Metallic Bonding:

While MOFs don’t exhibit traditional metallic bonding, this research shows how:

- Metal ions’ charge, size, and coordination number affect stability (same factors affecting metallic bond strength)

- Understanding metal-ligand bonding helps understand metal-metal bonding

- The spectrum from ionic to covalent to metallic bonding is continuous

Crystal Structures in Metallic Bonding

The arrangement of metal atoms in crystal lattices directly affects bonding strength, mechanical properties, and material behavior. Understanding crystal structures is essential for materials selection and alloy design.

Face-Centered Cubic (FCC)

Structural Characteristics:

- Atom positions: One atom at each corner of a cube (8 positions) plus one atom at the center of each face (6 positions)

- Coordination number: 12 (each atom touches 12 nearest neighbors)

- Atomic packing efficiency: 74% (highest possible for identical spheres)

- Atoms per unit cell: 4 effective atoms

- Calculation: 8 corner atoms × 1/8 (shared by 8 cells) + 6 face atoms × 1/2 (shared by 2 cells) = 1 + 3 = 4 atoms

Examples: Aluminum, copper, gold, silver, lead, nickel, platinum, calcium (at room temperature)

Properties:

FCC metals typically show:

- High ductility and malleability: Multiple slip systems (12 primary slip systems) allow easy deformation

- Moderate to high strength: High coordination number creates strong bonding

- Good electrical and thermal conductivity: Close packing facilitates electron movement

- Face-centered cubic is one of the most common metallic structures

Slip systems: FCC has {111} planes with <110> directions, providing 12 equivalent slip systems (4 planes × 3 directions). This abundance of slip systems makes FCC metals highly formable.

Real-world application: Aluminum’s FCC structure combined with low density (2.70 g/cm³) makes it ideal for aerospace. I’ve worked with aluminum alloys for aircraft skin, the material must be formable enough to create complex shapes yet strong enough for structural loads. FCC structure provides both.

Body-Centered Cubic (BCC)

Structural Characteristics:

- Atom positions: One atom at each corner of a cube plus one atom at the cube’s center

- Coordination number: 8 (nearest neighbors), though 6 more atoms are only slightly farther away

- Atomic packing efficiency: 68%

- Atoms per unit cell: 2 effective atoms

- Calculation: 8 corner atoms × 1/8 + 1 center atom = 1 + 1 = 2 atoms

Examples: Iron (at room temperature, α-iron), chromium, tungsten, molybdenum, sodium, potassium, lithium, vanadium

Properties:

BCC metals typically show:

- Higher strength but lower ductility than FCC: Fewer slip systems (48, but less favorable geometries)

- Temperature-dependent ductility: Become brittle at low temperatures (ductile-to-brittle transition)

- Good strength-to-weight ratio: Especially important for steel (iron-carbon alloy)

- Magnetic properties: Many BCC metals are ferromagnetic (iron, cobalt)

Slip systems: BCC has {110}, {112}, and {123} planes with <111> directions. While technically 48 slip systems exist, they’re not as favorably oriented as FCC slip systems, making BCC metals generally less ductile.

Temperature effects: BCC metals show a ductile-to-brittle transition temperature (DBTT). Above DBTT, they’re ductile; below DBTT, they become brittle. For pure iron, DBTT is around -20°C. This is why steel structures can fail catastrophically in extreme cold (like the Titanic).

Phase transitions: Iron undergoes interesting phase transitions:

- Room temperature to 912°C: BCC (α-iron/ferrite)

- 912°C to 1,394°C: FCC (γ-iron/austenite)

- 1,394°C to 1,538°C (melting point): BCC (δ-iron)

These transitions are fundamental to steel heat treatment and explain why steel can be hardened through controlled heating and cooling.

Hexagonal Close-Packed (HCP)

Structural Characteristics:

- Atom positions: Hexagonal arrangement with layers stacked in ABAB pattern

- Coordination number: 12 (same as FCC, different geometry)

- Atomic packing efficiency: 74% (same as FCC)

- Atoms per unit cell: 6 effective atoms

- Ideal c/a ratio: 1.633 (ratio of height to base dimension), though real metals vary

Examples: Magnesium, zinc, titanium, cobalt, cadmium, zirconium, beryllium

Properties:

HCP metals show:

- Anisotropic properties: Different properties in different crystallographic directions

- Generally lower ductility than FCC: Fewer independent slip systems (only 3 primary)

- Good strength: High coordination number creates strong bonding

- Variation with c/a ratio: Metals with c/a near ideal (1.633) show better ductility

Slip systems: HCP has primarily basal {0001} planes with <11̄20> directions, providing only 3 slip systems. Some HCP metals can activate prismatic and pyramidal slip at higher temperatures, improving formability.

Anisotropy: Because HCP structure has different atomic arrangements along different axes, properties vary with direction:

- Magnesium is much easier to deform parallel to basal planes than perpendicular

- This makes magnesium challenging to form at room temperature

- Zinc shows extreme anisotropy, very soft in certain directions, resistant in others

Real-world challenges: I’ve consulted on magnesium alloy development for automotive lightweighting. Magnesium’s HCP structure makes it notoriously difficult to form at room temperature. Most magnesium parts are either cast or formed at elevated temperatures (>225°C) where additional slip systems activate.

Comparison of Crystal Structures

| Property | FCC | BCC | HCP |

|---|---|---|---|

| Coordination number | 12 | 8 | 12 |

| Packing efficiency | 74% | 68% | 74% |

| Slip systems (primary) | 12 | 48* | 3 |

| Typical ductility | High | Moderate | Low to Moderate |

| Typical examples | Cu, Al, Au, Ag | Fe, Cr, W, Na | Mg, Zn, Ti |

| Anisotropy | Isotropic | Isotropic | Anisotropic |

*Note: While BCC has 48 mathematical slip systems, they’re less favorably oriented than FCC’s 12, so BCC is generally less ductile.

Importance of Crystal Structure

The crystal structure determines:

Mechanical behavior: How easily metal deforms (malleability/ductility) Number of nearest neighbors: Affects bonding strength (coordination number) Density: Higher packing efficiency = higher density (at constant atomic mass) Mechanical strength: More slip systems generally = better formability Temperature-dependent properties: Phase transitions change crystal structure Anisotropy: HCP shows directional properties; FCC/BCC are more isotropic

Alloy design consideration: When designing alloys, engineers often try to stabilize specific crystal structures:

- Adding carbon to iron stabilizes FCC (austenite) at lower temperatures

- Certain alloying elements stabilize BCC (ferrite) or HCP structures

- Controlling crystal structure is key to achieving desired properties

Types and Strengths of Metallic Bonds

Not all metallic bonds are created equal. Bond strength varies dramatically across the periodic table, creating metals with vastly different properties suitable for different applications.

Strong Metallic Bonds

Transition metals display the strongest metallic bonding due to their d-electrons participating in bonding, creating an extremely dense electron sea.

Characteristics:

- ✓ Extremely high melting points (tungsten: 3,422°C)

- ✓ Exceptional hardness and strength

- ✓ Superior electrical and thermal conductivity

- ✓ High resistance to deformation

- ✓ Dense crystal structures

- ✓ High boiling points

Examples with Applications:

Tungsten (W)

- Melting point: 3,422°C (highest of all metals)

- Uses: Light bulb filaments, rocket nozzles, armor-piercing ammunition

- Why it’s special: Can withstand extreme temperatures without melting

Chromium (Cr)

- Melting point: 1,907°C

- Uses: Stainless steel production (10-30% chromium content), chrome plating

- Why it’s special: Forms protective oxide layer preventing corrosion

Titanium (Ti)

- Melting point: 1,668°C

- Uses: Aircraft components, medical implants, sporting equipment

- Why it’s special: High strength-to-weight ratio with excellent biocompatibility

Osmium (Os)

- Density: 22.59 g/cm³ (densest naturally occurring element)

- Uses: Fountain pen tips, electrical contacts, specialized alloys

- Why it’s special: Extremely hard and corrosion-resistant

💡 Real-World Example: Jet Engine Turbine Blades

Modern jet engines operate at temperatures exceeding 1,500°C. Turbine blades are made from nickel-based superalloys with strong metallic bonding that maintains strength at these extreme temperatures. A single engine contains 100+ blades, each costing $10,000-20,000 due to the specialized alloy composition and manufacturing process.

Moderate Metallic Bonds

Post-transition metals and heavier alkaline earth metals exhibit moderate bonding strength, offering an excellent balance of workability and performance.

Characteristics:

- Moderate melting points (aluminum: 660°C; copper: 1,085°C)

- Good balance of strength and workability

- Excellent electrical and thermal conductivity

- Suitable for everyday applications

- Easier to machine and form than transition metals

Examples with Applications:

Aluminum (Al)

- Melting point: 660°C

- Conductivity: 3.5 × 10⁷ S/m

- Uses: Aircraft bodies, beverage cans, window frames, power transmission lines

- Key property: Lightweight (2.70 g/cm³) with good strength

Copper (Cu)

- Melting point: 1,085°C

- Conductivity: 5.96 × 10⁷ S/m (second only to silver)

- Uses: Electrical wiring, plumbing pipes, heat exchangers, circuit boards

- Key property: Best conductivity-to-cost ratio

Zinc (Zn)

- Melting point: 420°C

- Uses: Galvanizing steel, brass production, die casting

- Key property: Excellent corrosion protection for steel

Nickel (Ni)

- Melting point: 1,455°C

- Uses: Stainless steel, batteries, electroplating, superalloys

- Key property: Excellent corrosion resistance and high-temperature stability

💡 Real-World Example: Aluminum Beverage Cans

An aluminum can weighs just 13 grams but can withstand 90 psi of internal pressure. The moderate metallic bonding allows the aluminum to be formed into complex shapes while maintaining strength. Over 100 billion cans are produced annually, and aluminum’s recyclability (can be recycled indefinitely without quality loss) stems from its metallic bonding structure remaining intact through melting and reforming.

Weak Metallic Bonds

Alkali metals show the weakest metallic bonding, contributing only one electron per atom with large atomic radii resulting in low charge density.

Characteristics:

- ✓ Very low melting points (cesium: 28.5°C; gallium: 29.8°C)

- ✓ Soft enough to cut with a knife

- ✓ High chemical reactivity

- ✓ Low density (lithium floats on water)

- ✓ Good electrical conductivity despite weak bonding

- ✓ Highly reactive with water and oxygen

Examples with Applications:

Lithium (Li)

- Melting point: 180°C

- Uses: Lithium-ion batteries, psychiatric medication, specialized lubricants

- Why it’s important: Essential for electric vehicle revolution

Sodium (Na)

- Melting point: 98°C

- Uses: Sodium vapor lamps, heat transfer in nuclear reactors, chemical synthesis

- Reactivity: Reacts violently with water

Potassium (K)

- Melting point: 63°C

- Uses: Fertilizers (as compounds), chemical synthesis, specialized optical glasses

- Key property: Essential nutrient for plants and animals

Cesium (Cs)

- Melting point: 28.5°C (melts slightly above room temperature)

- Uses: Atomic clocks (most accurate time measurement), photoelectric cells

- Special note: Defines the second (SI unit) via atomic transitions

Gallium (Ga)

- Melting point: 29.8°C (melts in your hand!)

- Uses: LEDs, semiconductors, solar panels

- Unique property: Expands when solidifying (like water)

💡 Real-World Example: Lithium-Ion Batteries

Your smartphone, laptop, and electric vehicle all rely on lithium’s weak metallic bonding. Lithium readily gives up its single valence electron, making it ideal for battery applications. Each Tesla Model 3 contains about 11 kg of lithium. The global lithium battery market reached $44 billion in 2024 and continues growing exponentially with electric vehicle adoption.

Alloy Bonding: The Best of Both Worlds

Alloys create complex metallic bonding situations where different metal atoms combine, often producing properties superior to pure metals.

Substitutional Alloys: Different-sized atoms replace some lattice positions. The size mismatch disrupts atomic layers, making the alloy stronger and harder than pure metals.

Examples:

- Brass: 60-70% copper + 30-40% zinc (door handles, musical instruments)

- Bronze: 88% copper + 12% tin (ship propellers, sculptures)

- Sterling Silver: 92.5% silver + 7.5% copper (jewelry, silverware)

Interstitial Alloys: Small atoms fit into spaces between larger ones, preventing layers from sliding and dramatically increasing strength.

Examples:

- Steel: Iron + 0.2-2% carbon (construction, automotive, tools)

- Stainless Steel: Iron + chromium + nickel + carbon (kitchenware, medical instruments)

- Tool Steel: Iron + tungsten/vanadium/chromium (cutting tools, dies)

💡 Real-World Example: Stainless Steel Kitchen Sinks

Your kitchen sink is likely made from 304 stainless steel (18% chromium, 8% nickel, balance iron). The chromium creates a self-healing passive oxide layer that prevents rust, while nickel enhances corrosion resistance. The complex metallic bonding in this alloy makes it stronger than pure iron while maintaining workability. Stainless steel has a 50+ year lifespan in typical kitchen conditions.

Key Properties of Metallic Bonds

Metallic bonding gives rise to five distinctive properties that define metallic behavior and make metals indispensable in modern technology.

1. Electrical Conductivity ⚡

The Mechanism: Delocalized electrons move freely when an electrical potential is applied, creating current flow from high to low potential regions. Unlike ionic conductors (which require ions to physically move), metals conduct via electron flow, which is nearly instantaneous.

Why It Matters:

- Enables all electrical and electronic applications

- Critical for power generation, transmission, and distribution

- Essential for circuits, motors, and telecommunications

- Foundation of modern information technology

Best Conductors (Conductivity in S/m):

| Metal | Conductivity | Primary Uses |

|---|---|---|

| Silver | 6.30 × 10⁷ | High-end audio cables, electrical contacts |

| Copper | 5.96 × 10⁷ | Power cables, wiring, electronics |

| Gold | 4.52 × 10⁷ | Computer processors, connectors |

| Aluminum | 3.77 × 10⁷ | Power transmission lines, aerospace |

Temperature Effects: Conductivity decreases as temperature rises because increased atomic vibrations scatter electrons, impeding their flow. This is why superconductors (which have zero resistance) only work at very low temperatures.

Formula: Resistance increases with temperature: R_T = R_0[1 + α(T – T_0)]

Where α is the temperature coefficient of resistance.

💡 Real-World Example: Smartphone Circuit Boards

Your smartphone contains over 15 kilometers of copper traces on its circuit boards, each thinner than a human hair. These traces connect billions of transistors, utilizing metallic bonding’s conductivity to process 100+ billion operations per second. The gold-plated connectors use gold’s superior corrosion resistance to ensure reliable connections for years of use.

2. Thermal Conductivity 🔥

How It Works: When heated, high-energy electrons rapidly spread kinetic energy throughout the electron sea via collisions with atoms and other electrons. This electron-mediated heat transfer is much faster than phonon-only conduction in non-metals.

Applications:

- Heat sinks in computers and electronics (prevent overheating)

- Cookware and kitchen utensils (even heat distribution)

- Industrial heat exchangers (efficient energy transfer)

- Radiators and cooling systems (temperature regulation)

- Thermal management in smartphones and data centers

Performance Rankings (Thermal Conductivity in W/(m·K)):

| Metal | Thermal Conductivity | Common Applications |

|---|---|---|

| Silver | 429 | Specialized thermal paste |

| Copper | 401 | Heat sinks, cookware |

| Gold | 318 | High-performance electronics |

| Aluminum | 237 | Automotive radiators, cookware |

| Brass | 109 | Moderate heat applications |

| Stainless Steel | 16 | Poor conductor despite being metallic |

Why Some Metals Conduct Heat Poorly: Stainless steel’s alloy composition creates interruptions in the electron sea, dramatically reducing thermal conductivity compared to pure metals. This makes it suitable for cooking handles that won’t get too hot!

💡 Real-World Example: Laptop Heat Sinks

Modern laptop CPUs generate 45-100 watts of heat in a tiny space. Copper heat sinks with heat pipes utilize metallic bonding’s thermal conductivity to transfer this heat away from the processor at over 400 W/(m·K). Without this efficient heat removal, your laptop would overheat and shut down within seconds. High-performance gaming laptops use vapor chambers, advanced copper structures that can dissipate 200+ watts continuously.

3. Malleability and Ductility 🔨

Malleability refers to a metal’s ability to be hammered or pressed into thin sheets without breaking, while ductility describes the ability to be drawn into wires.

Why Metals Bend Without Breaking: Non-directional bonding allows layers of atoms to slide past each other without breaking bonds. The electron sea continues providing cohesion throughout the structure regardless of atomic positions, maintaining bonding even as the metal’s shape changes dramatically.

Contrast with Ionic Crystals: When you try to deform an ionic crystal, shifting layers brings like charges together (positive near positive, negative near negative). This creates repulsion that shatters the structure, explaining why salt crystals break rather than bend.

Impressive Examples:

Gold Malleability:

- Can be hammered into sheets just 0.00001 cm thick (gold leaf)

- One gram of gold can be beaten into a 1-square-meter sheet

- Gold leaf is so thin it’s translucent (appears greenish-blue when light passes through)

- Uses: Gilding on buildings, decorative arts, radiation shielding in spacecraft

Copper Ductility:

- Can be drawn into wires thinner than human hair (20 micrometers diameter)

- One kilogram of copper can produce 230 kilometers of 25-micrometer wire

- Used in telecommunications, power transmission, and electronics

- Global copper wire production exceeds 20 million tons annually

Aluminum Versatility:

- Can be rolled into foil just 0.006 mm thick (household aluminum foil)

- Typical aluminum foil is 10-20 micrometers thick

- Also highly ductile, used for power transmission cables

- 75% of all aluminum ever produced is still in use due to recyclability

Steel Formability:

- Can be shaped into complex automotive components via stamping and forming

- Cold-working increases strength (work hardening)

- Used in everything from paper clips to bridge cables

Exceptions: Some metals and alloys are brittle due to complex crystal structures, internal defects, or grain boundary issues. Cast iron, for example, contains graphite flakes that act as crack initiation sites, making it brittle despite being metallic.

💡 Real-World Example: Aircraft Aluminum

A Boeing 747 contains over 66,000 kg of aluminum alloy formed into complex curved shapes for the fuselage, wings, and internal structures. The aluminum’s malleability allows these shapes to be formed through stamping and rolling, while its ductility permits riveting without cracking. Each aircraft uses 6+ million rivets, all installed relying on aluminum’s deformation properties. The same aluminum panels can be recycled indefinitely, with 90% of decommissioned aircraft aluminum being reused.

4. Metallic Luster ✨