Quick Answer: Types of Chromatography

What are the main types of chromatography?

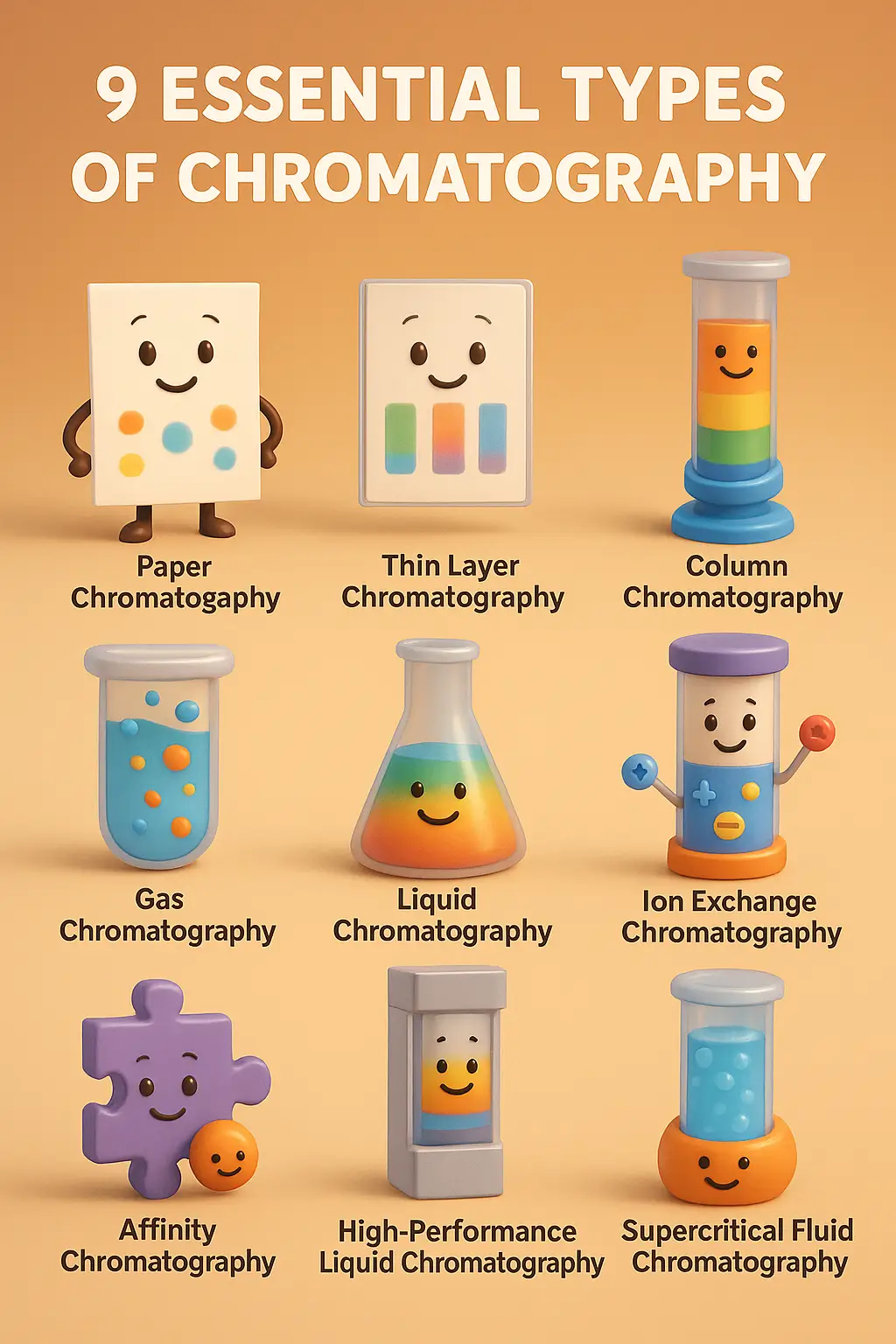

The 9 essential types of chromatography are:

- High-Performance Liquid Chromatography (HPLC) – Industry standard for precise analysis

- Gas Chromatography (GC) – Best for volatile compounds

- Gas Chromatography-Mass Spectrometry (GC-MS) – Combines separation with identification

- Ultra-High-Performance Liquid Chromatography (UHPLC) – Fastest, highest resolution

- Liquid Chromatography-Mass Spectrometry (LC-MS) – For complex molecular analysis

- Ion Exchange Chromatography (IEX) – Separates charged molecules

- Size Exclusion Chromatography (SEC) – Separates by molecular size

- Affinity Chromatography – Highly selective biological separations

- Thin Layer Chromatography (TLC) – Simple, cost-effective screening

Which chromatography type should I use?

- For routine drug analysis: HPLC

- For volatile organics: GC or GC-MS

- For protein purification: Ion exchange or affinity

- For quick screening: TLC

- For maximum speed: UHPLC

What is chromatography used for?

- Pharmaceutical quality control and drug testing

- Food safety and contaminant detection

- Environmental pollution monitoring

- Forensic evidence analysis

- Research and compound purification

Table of Contents

What is Chromatography? Understanding the Scientific Foundation

Chromatography stands as one of the most revolutionary separation techniques in modern analytical chemistry.

At its core, this powerful method separates mixtures by exploiting the differential movement of components between two distinct phases: a stationary phase that remains fixed and a mobile phase that continuously moves.

The fundamental principle is elegantly simple yet scientifically profound: different compounds in a mixture interact uniquely with both phases, causing them to migrate at different rates. This differential migration creates spatial separation, allowing scientists to isolate, identify, and quantify individual components from complex mixtures.

Why Chromatography Matters: Real-World Impact and Applications

Critical Applications Across Industries

- Pharmaceutical Quality Control: Ensuring drug purity and detecting harmful impurities

- Food Safety Testing: Identifying pesticide residues and contaminants in food products

- Environmental Monitoring: Detecting pollutants in air, water, and soil samples

- Forensic Investigations: Analyzing evidence in criminal cases and toxicology studies

- Clinical Diagnostics: Monitoring therapeutic drug levels and biomarkers

- Research & Development: Purifying compounds and studying molecular interactions

The 9 Essential Types of Chromatography: Detailed Analysis

1. High-Performance Liquid Chromatography (HPLC): The Industry Gold Standard

HPLC represents the pinnacle of liquid chromatographic technology, utilizing high pressure (up to 1000 bar) to force mobile phases through columns packed with ultra-fine particles (1.7-5 μm diameter).

Key Technical Specifications:

- Pressure Range: 200-1000 bar

- Particle Size: 1.7-10 μm

- Analysis Time: 5-60 minutes

- Resolution: Exceptional (>1.5 typically)

- Sensitivity: ng to pg levels

Primary Applications:

- Pharmaceutical Analysis: Drug assay, impurity profiling, stability testing

- Biochemical Research: Protein analysis, metabolomics studies

- Quality Control: Raw material testing, final product analysis

- Clinical Testing: Therapeutic drug monitoring, biomarker analysis

Advantages:

- Superior resolution and reproducibility

- Automated operation with minimal manual intervention

- Quantitative accuracy with excellent precision

- Wide range of detection options (UV, fluorescence, MS)

Limitations:

- High operational costs (solvents, columns, maintenance)

- Limited to thermally stable, non-volatile compounds

- Requires skilled operators for method development

2. Gas Chromatography (GC): Master of Volatile Compound Analysis

Gas Chromatography excels in separating volatile and semi-volatile organic compounds using an inert gas carrier (helium, nitrogen, or hydrogen) as the mobile phase.

Technical Parameters:

- Temperature Range: 40-400°C

- Column Length: 15-100 meters (capillary)

- Carrier Gas Flow: 0.5-5 mL/min

- Analysis Time: 10-90 minutes

- Volatility Requirement: Compounds must vaporize without decomposition

Core Applications:

- Environmental Analysis: VOCs, pesticides, petroleum hydrocarbons

- Forensic Science: Drug identification, accelerant analysis

- Food Industry: Flavor compounds, residual solvents, fatty acid analysis

- Petrochemical Industry: Hydrocarbon analysis, fuel quality testing

Key Benefits:

- Exceptional resolution for complex mixtures

- High sensitivity and selectivity

- Excellent quantitative capabilities

- Relatively low operating costs

Constraints:

- Limited to volatile/semi-volatile compounds

- Sample derivatization often required

- Thermal decomposition risk for labile compounds

3. Gas Chromatography-Mass Spectrometry (GC-MS): The Identification Powerhouse

GC-MS combines the separation power of gas chromatography with the identification capabilities of mass spectrometry, creating an unparalleled analytical tool for compound identification and quantification.

Technical Capabilities:

- Mass Range: 10-1000 m/z (typical)

- Detection Limits: pg to fg levels

- Scan Speed: Up to 20,000 amu/second

- Library Database: >275,000 compounds (NIST)

- Ionization Methods: EI, CI, APCI

Critical Applications:

- Drug Testing: Confirmation of controlled substances

- Environmental Forensics: Contamination source identification

- Food Safety: Pesticide multi-residue analysis

- Clinical Toxicology: Poison identification, metabolite analysis

- Security Screening: Explosives and chemical warfare agents

Superior Features:

- Definitive compound identification

- Structural elucidation capabilities

- Excellent sensitivity and specificity

- Extensive compound libraries available

Operational Challenges:

- High equipment and maintenance costs

- Complex data interpretation requirements

- Need for experienced operators

- Limited to GC-compatible compounds

4. Ultra-High-Performance Liquid Chromatography (UHPLC): Next-Generation Speed and Resolution

UHPLC pushes the boundaries of liquid chromatography with sub-2-micron particles and pressures exceeding 1000 bar, delivering unprecedented speed and resolution.

Advanced Specifications:

- Pressure Capability: Up to 1500 bar

- Particle Size: 1.3-1.8 μm

- Analysis Time: 1-15 minutes

- Theoretical Plates: >20,000 per meter

- Peak Capacity: 300-1000

Revolutionary Applications:

- High-Throughput Analysis: Rapid sample processing

- Complex Mixture Resolution: Natural product analysis

- Impurity Profiling: Pharmaceutical quality control

- Metabolomics: Comprehensive metabolite analysis

5. Liquid Chromatography-Mass Spectrometry (LC-MS): Comprehensive Molecular Analysis

LC-MS integrates liquid chromatography separation with mass spectrometric detection, enabling analysis of non-volatile, thermally labile, and polar compounds.

Technical Excellence:

- Ionization Methods: ESI, APCI, APPI

- Mass Accuracy: <2 ppm (high-resolution systems)

- Dynamic Range: 4-6 orders of magnitude

- MS/MS Capability: Structural confirmation

- Quantitation Limits: pg/mL levels

Essential Applications:

- Proteomics: Protein identification and quantification

- Pharmaceutical Development: DMPK studies, bioanalysis

- Clinical Diagnostics: Biomarker discovery and validation

- Environmental Studies: Emerging contaminant analysis

6. Ion Exchange Chromatography (IEX): Charge-Based Separations

Ion Exchange Chromatography separates molecules based on their net charge and charge density using stationary phases containing ionic functional groups.

Mechanism and Types:

- Cation Exchange: Separates positively charged molecules

- Anion Exchange: Separates negatively charged molecules

- pH Optimization: Critical for protein separations

- Salt Gradient: Controls elution strength

- Binding Capacity: 50-200 mg/mL resin

Specialized Applications:

- Protein Purification: Monoclonal antibodies, enzymes

- Water Treatment: Ion removal, water softening

- Pharmaceutical Biotechnology: Biotherapeutic purification

- Food Processing: Amino acid purification, sugar processing

Operational Advantages:

- High capacity for sample loading

- Excellent resolution for charged species

- Scalable from analytical to industrial levels

- Regenerable stationary phases

7. Size Exclusion Chromatography (SEC): Molecular Size-Based Separation

Size Exclusion Chromatography separates molecules based on their hydrodynamic volume, with larger molecules eluting first and smaller molecules eluting later.

Fundamental Principles:

- Pore Size Distribution: Controls separation range

- Molecular Weight Range: 100 Da to 10 MDa

- Non-Adsorptive Mechanism: Preserves native structure

- Isocratic Elution: Single mobile phase composition

- Gentle Conditions: Maintains biological activity

Key Applications:

- Molecular Weight Determination: Protein and polymer characterization

- Protein Aggregation Analysis: Biopharmaceutical quality control

- Buffer Exchange: Sample preparation and formulation

- Complex Formation Studies: Protein-protein interactions

8. Affinity Chromatography: Biospecific Separations

Affinity Chromatography achieves highly selective separations through specific biological interactions between target molecules and immobilized ligands.

Biorecognition Elements:

- Antibodies: Immunoaffinity purification

- Enzymes: Substrate-specific binding

- Lectins: Carbohydrate recognition

- Protein A/G: Antibody purification

- Metal Chelates: His-tag protein purification

Specialized Uses:

- Recombinant Protein Purification: Single-step high purity

- Biomarker Isolation: Clinical sample preparation

- Vaccine Production: Antigen purification

- Diagnostic Applications: Capture and concentration

9. Thin Layer Chromatography (TLC): Simple and Versatile

Thin Layer Chromatography provides rapid, cost-effective separations using thin layers of adsorbent material coated on solid supports.

System Components:

- Stationary Phases: Silica gel, alumina, cellulose

- Mobile Phases: Single solvents or mixtures

- Detection Methods: UV light, chemical staining, fluorescence

- Rf Values: Compound identification parameters

- Development Time: 15-60 minutes

Practical Applications:

- Reaction Monitoring: Synthetic chemistry progress tracking

- Purity Assessment: Qualitative compound evaluation

- Educational Training: Chromatography principle demonstration

- Method Development: Mobile phase optimization

Chromatography Selection Guide: Making the Right Choice

Decision Matrix for Method Selection

| Analysis Goal | Recommended Technique | Key Considerations |

|---|---|---|

| Rapid quantitative analysis | UHPLC | Speed, automation, high throughput |

| Compound identification | GC-MS or LC-MS | Structural information needed |

| Large-scale purification | Preparative LC | Sample capacity requirements |

| Protein characterization | SEC + IEX | Native structure preservation |

| Volatile organics | GC | Thermal stability, volatility |

| Preliminary screening | TLC | Cost, speed, simplicity |

| Biospecific isolation | Affinity | Maximum selectivity required |

Critical Selection Factors

1. Sample Properties Assessment

- Molecular weight range (small molecules vs. proteins)

- Chemical stability (thermal, pH, oxidation)

- Solubility characteristics (polar, non-polar, ionic)

- Volatility and thermal decomposition temperature

2. Analytical Requirements

- Qualitative vs. Quantitative: Identification or measurement needs

- Sensitivity Requirements: Detection limits needed

- Resolution Demands: Separation difficulty assessment

- Throughput Expectations: Number of samples per day

3. Economic Considerations

- Initial equipment investment

- Ongoing operational costs (solvents, columns, maintenance)

- Personnel training requirements

- Method development time and complexity

Advanced Chromatography Trends and Future Developments

Emerging Technologies

Green Chromatography Initiatives

- Supercritical Fluid Chromatography (SFC): CO2-based mobile phases

- Hydrophilic Interaction Chromatography (HILIC): Reduced organic solvent use

- Miniaturized Systems: Decreased reagent consumption

- Sustainable Stationary Phases: Biodegradable materials

Automation and AI Integration

- Intelligent Method Development: Machine learning optimization

- Automated Troubleshooting: Expert system guidance

- Predictive Maintenance: Equipment reliability enhancement

- Real-time Quality Control: Continuous process monitoring

Multi-dimensional Separations

- 2D-LC Systems: Orthogonal separation mechanisms

- Comprehensive GC×GC: Enhanced peak capacity

- LC-GC Interfaces: Complementary technique coupling

- Online Sample Preparation: Integrated workflows

Common Chromatography Challenges and Solutions

1. Peak Tailing and Broadening

Causes: Column overloading, extra-column volume, poor mobile phase quality Solutions: Reduce injection volume, optimize flow rate, use HPLC-grade solvents

2. Poor Resolution

Causes: Inappropriate stationary phase, suboptimal mobile phase composition Solutions: Gradient optimization, column selection, temperature adjustment

3. Baseline Drift and Noise

Causes: Temperature fluctuations, contaminated mobile phases, detector issues Solutions: Environmental control, solvent purification, regular maintenance

4. Retention Time Variability

Causes: Temperature variations, mobile phase composition changes, column aging Solutions: Column thermostating, precise mobile phase preparation, internal standards

Quality Assurance and Method Validation

Essential Validation Parameters

- Accuracy: Closeness to true value

- Precision: Reproducibility of results

- Linearity: Response proportionality

- Range: Validated concentration span

- Detection Limit: Minimum detectable quantity

- Quantitation Limit: Minimum quantifiable amount

- Robustness: Method reliability under varied conditions

- Specificity: Interference-free analysis

Regulatory Compliance Standards

- ICH Guidelines: International pharmaceutical standards

- USP Methods: United States Pharmacopeia requirements

- EPA Methods: Environmental analysis protocols

- ISO Standards: International quality management

- FDA Guidance: Drug development and approval

Industry-Specific Applications and Case Studies

Pharmaceutical Industry Excellence

Drug Development Pipeline

- Discovery Phase: Compound library analysis and screening

- Development Phase: Impurity identification and quantification

- Manufacturing: Raw material testing and process monitoring

- Quality Control: Batch release testing and stability studies

- Regulatory Submission: Method validation and documentation

Biopharmaceutical Challenges

- Protein Aggregation: Size exclusion chromatography monitoring

- Charge Variants: Ion exchange characterization

- Post-translational Modifications: Mass spectrometry analysis

- Glycosylation Profiling: HILIC-MS methodology

Environmental Analysis Excellence

Water Quality Assessment

- Drinking Water: Pesticide and pharmaceutical residue analysis

- Wastewater: Emerging contaminant detection

- Groundwater: Petroleum hydrocarbon contamination

- Surface Water: Algal toxin and heavy metal analysis

Air Quality Monitoring

- VOC Analysis: Industrial emission monitoring

- Indoor Air Quality: Building contamination assessment

- Atmospheric Research: Climate change gas analysis

- Occupational Health: Workplace exposure evaluation

Food Safety and Quality Control

Contaminant Detection

- Pesticide Residues: Multi-residue screening methods

- Mycotoxins: Fungal contamination analysis

- Food Additives: Preservative and colorant quantification

- Allergens: Cross-contamination detection

Nutritional Analysis

- Vitamin Content: Fat and water-soluble vitamin analysis

- Amino Acid Profiling: Protein quality assessment

- Fatty Acid Composition: Lipid characterization

- Antioxidant Capacity: Polyphenol quantification

Cost-Benefit Analysis and Return on Investment

Total Cost of Ownership Calculation

Initial Investment Components

- Equipment purchase price

- Installation and setup costs

- Method development time

- Operator training expenses

- Regulatory compliance costs

Ongoing Operational Expenses

- Mobile phase and reagent consumption

- Stationary phase replacement

- Preventive maintenance contracts

- Utility costs (electricity, gases, water)

- Labor costs for operation and maintenance

Hidden Costs Often Overlooked

- Equipment downtime and lost productivity

- Failed analysis rework costs

- Regulatory compliance failures

- Quality issues and product recalls

- Opportunity costs of delayed results

ROI Optimization Strategies

- Right-sizing Equipment: Match capacity to actual needs

- Automation Investment: Reduce labor costs and errors

- Preventive Maintenance: Minimize unexpected downtime

- Cross-training Personnel: Increase operational flexibility

- Standardized Methods: Reduce development time and costs

Expert Tips for Chromatography Success

Method Development Best Practices

1. Comprehensive Sample Characterization

- Determine molecular weight, pKa, log P values

- Assess thermal and chemical stability

- Evaluate solubility in various solvents

- Consider sample matrix effects

2. Systematic Approach to Optimization

- Start with literature methods or similar compounds

- Use design of experiments (DoE) for efficiency

- Optimize one parameter at a time initially

- Validate robustness of final conditions

3. Column Selection Strategy

- Consider stationary phase chemistry

- Evaluate particle size and column dimensions

- Test multiple column types if needed

- Consider column lifetime and cost

Troubleshooting Methodology

Systematic Problem Diagnosis

- Identify Symptoms: Document all observed issues

- Check Recent Changes: Equipment, methods, personnel

- Review Maintenance Records: Identify potential causes

- Test Components Systematically: Isolate problem source

- Implement Solutions Incrementally: Avoid multiple changes

Preventive Measures

- Establish baseline performance metrics

- Monitor trends in system performance

- Implement regular preventive maintenance

- Train staff on proper operating procedures

- Maintain detailed documentation

Conclusion: Mastering Chromatography Selection

Chromatography represents one of the most powerful and versatile analytical tool families available to modern scientists. Success in chromatographic analysis depends on understanding the fundamental principles underlying each technique and matching these capabilities to specific analytical challenges.

The nine essential chromatography types covered in this guide each offer unique advantages and serve specific applications. HPLC and UHPLC provide exceptional resolution and automation for routine analysis. GC and GC-MS excel in volatile compound analysis and identification. LC-MS enables comprehensive molecular characterization. Specialized techniques like ion exchange, size exclusion, and affinity chromatography address specific separation challenges.

Key Success Factors:

- Thorough sample characterization before method selection

- Systematic approach to method development and optimization

- Comprehensive validation following regulatory guidelines

- Continuous monitoring of system performance and maintenance

- Investment in training for personnel at all levels

- Strategic planning for future needs and technology evolution

The future of chromatography continues to evolve with advances in instrumentation, automation, and data analysis. Green chemistry initiatives, miniaturization trends, and artificial intelligence integration promise to enhance capabilities while reducing environmental impact and operational costs.

By applying the principles and strategies outlined in this comprehensive guide, analysts can make informed decisions about chromatographic method selection, avoid common pitfalls, and achieve reliable, cost-effective separations that meet their analytical objectives.

Whether you’re analyzing pharmaceutical impurities, monitoring environmental contaminants, ensuring food safety, or conducting cutting-edge research, the appropriate chromatographic technique exists to meet your needs. The key lies in understanding the options available and making informed decisions based on scientific principles and practical considerations.

For those seeking to expand their separation expertise further, exploring comprehensive guides on different types of separation techniques will provide valuable insights into how filtration fits within the broader landscape of separation science and help you develop integrated approaches to complex separation challenges.

Carriers in Chromatography: The Foundation of Separation

What are Carriers in Chromatography?

Carriers (also called mobile phases) are the substances that transport sample components through the chromatographic system. The choice of carrier is critical for achieving optimal separation, resolution, and detection.

Types of Carriers by Chromatography Method

Gas Chromatography Carriers

- Helium (He): Most common, provides excellent resolution and MS compatibility

- Nitrogen (N2): Cost-effective, good for routine analysis with FID detection

- Hydrogen (H2): Fastest analysis times, highest efficiency, requires safety precautions

- Argon (Ar): Specialized applications, used with electron capture detectors

Carrier Gas Selection Criteria:

- Purity Requirements: >99.999% for trace analysis

- Flow Rate Optimization: 0.5-5 mL/min depending on column

- Detector Compatibility: Some detectors require specific gases

- Safety Considerations: Hydrogen requires special handling

- Cost Factors: Helium most expensive, nitrogen most economical

Liquid Chromatography Mobile Phases

- Water-based Systems: HPLC, ion exchange, size exclusion

- Organic Solvents: Methanol, acetonitrile, isopropanol

- Buffer Solutions: pH control for ionizable compounds

- Supercritical Fluids: CO2 for green chemistry applications

Mobile Phase Composition Factors:

- pH Optimization: Critical for ionizable compounds (pH 2-12 range)

- Ionic Strength: Affects retention in ion exchange chromatography

- Organic Content: Controls hydrophobic interactions (0-100%)

- Gradient Programming: Time-varying composition for complex separations

Carrier Optimization Strategies

Gas Chromatography Optimization

- Linear Velocity Optimization: Use van Deemter plots

- Pressure Programming: Constant flow vs. constant pressure

- Temperature Effects: Higher temperature = faster carrier flow

- Column Compatibility: Match carrier to stationary phase

Liquid Chromatography Optimization

- Solvent Strength: Adjust organic modifier percentage

- pH Buffering: Maintain consistent ionization state

- Gradient Development: Optimize slope and duration

- Additive Selection: Ion-pairing agents, salts, acids, bases

Career Opportunities in Chromatography: Building Your Professional Path

Why Choose a Career in Chromatography?

Chromatography careers offer excellent opportunities in rapidly growing industries with strong job security, competitive salaries, and intellectual challenges. The global chromatography market is projected to reach $15.2 billion by 2028, creating numerous career paths across multiple industries.

Career Paths by Industry Sector

Pharmaceutical & Biotechnology Careers

| Career Role | Primary Responsibility | Salary Range (USD) |

|---|---|---|

| Analytical Chemist | Method development and validation | $65,000 – $95,000 |

| Quality Control Analyst | Product testing and compliance | $55,000 – $80,000 |

| Research Scientist | Drug discovery and development | $75,000 – $120,000 |

| Regulatory Affairs Specialist | FDA submissions and compliance | $70,000 – $105,000 |

Required Skills:

- Technical Expertise: HPLC, GC-MS, LC-MS proficiency

- Regulatory Knowledge: ICH, USP, FDA guidelines

- Problem Solving: Method troubleshooting and optimization

- Documentation: GMP record keeping and validation protocols

Environmental & Government Careers

| Career Role | Primary Responsibility | Salary Range (USD) |

|---|---|---|

| Environmental Analyst | Pollution monitoring and assessment | $50,000 – $75,000 |

| Forensic Scientist | Criminal investigation and evidence analysis | $55,000 – $85,000 |

| EPA Inspector | Regulatory compliance and enforcement | $60,000 – $90,000 |

| Research Scientist | Climate and environmental studies | $65,000 – $100,000 |

Key Competencies:

- Environmental Regulations: EPA methods, clean air/water acts

- Field Sampling: Sample collection and preservation techniques

- Data Analysis: Statistical analysis and reporting

- Legal Knowledge: Court testimony and chain of custody

Food & Agricultural Industry

| Career Role | Primary Responsibility | Salary Range (USD) |

|---|---|---|

| Food Safety Analyst | Contamination detection and prevention | $50,000 – $70,000 |

| Quality Assurance Manager | Product safety and compliance | $65,000 – $90,000 |

| Nutritional Scientist | Product development and labeling | $60,000 – $85,000 |

| Agricultural Researcher | Pesticide analysis and crop studies | $55,000 – $80,000 |

Academic & Research Institutions

| Career Role | Primary Responsibility | Salary Range (USD) |

|---|---|---|

| University Professor | Teaching and research | $70,000 – $150,000 |

| Postdoctoral Researcher | Advanced research projects | $45,000 – $65,000 |

| Laboratory Manager | Facility operations and management | $60,000 – $95,000 |

| Instrumentation Specialist | Equipment maintenance and training | $55,000 – $80,000 |

Educational Requirements and Career Development

Entry-Level Positions

- Bachelor’s Degree: Chemistry, biochemistry, or related field

- Laboratory Experience: Internships or undergraduate research

- Instrument Training: Hands-on chromatography experience

- Analytical Skills: Data interpretation and report writing

Advanced Career Growth

- Master’s Degree: Specialized analytical chemistry focus

- PhD Requirements: Independent research and method development

- Professional Certifications: ACS, AOAC, or industry-specific credentials

- Continuing Education: Regular training on new technologies

Essential Skills for Career Success

- Technical Proficiency: Multiple chromatography techniques

- Software Skills: Data analysis and laboratory information systems

- Communication: Technical writing and presentation abilities

- Project Management: Method development and validation timelines

- Regulatory Understanding: Industry-specific compliance requirements

Career Advancement Strategies

Professional Development Opportunities

- Industry Conferences: PITTCON, ACS meetings, specialized symposiums

- Professional Organizations: American Chemical Society, AOAC International

- Certification Programs: Instrument-specific training and credentials

- Networking: Building relationships with industry professionals

- Publications: Contributing to peer-reviewed journals

Salary Progression and Benefits

| Level / Title | Experience | Salary Range (USD) |

|---|---|---|

| Entry Level | 0–2 years | $45,000 – $65,000 |

| Mid-Level | 3–7 years | $60,000 – $85,000 |

| Senior Level | 8–15 years | $80,000 – $120,000 |

| Management / Director | Leadership | $100,000 – $180,000+ |

Additional Benefits:

- Health insurance and retirement plans

- Professional development funding

- Flexible work arrangements

- Patent bonuses and profit sharing

- International travel opportunities

Emerging Career Opportunities

Technology Integration Roles

- Data Scientists: AI/ML applications in chromatography

- Automation Specialists: Laboratory robotics and workflow optimization

- Software Developers: Instrument control and data analysis software

- Digital Transformation: Laboratory digitization and Industry 4.0

Entrepreneurial Opportunities

- Consulting Services: Method development and validation

- Contract Research Organizations: Analytical testing services

- Instrumentation Companies: Sales, applications, and technical support

- Start-up Companies: Innovative chromatography technologies

Geographic Career Markets

Major Employment Hubs

- Boston/Cambridge: Biotechnology and pharmaceutical companies

- San Francisco Bay Area: Biotechnology and environmental companies

- Research Triangle (NC): Pharmaceutical and contract research

- New Jersey: Major pharmaceutical headquarters

- Washington DC: Government agencies and regulatory bodies

International Opportunities

- Europe: Basel (Switzerland), Cambridge (UK), Frankfurt (Germany)

- Asia-Pacific: Singapore, Tokyo, Shanghai biotech hubs

- Emerging Markets: India, Brazil pharmaceutical manufacturing

Career Success Tips

Building Technical Expertise

- Master Multiple Techniques: Don’t limit yourself to one method

- Stay Current: Follow latest technology developments

- Develop Troubleshooting Skills: Become the go-to problem solver

- Understand Applications: Know when and why to use each technique

Professional Network Development

- Join Professional Organizations: Active participation and volunteer work

- Attend Industry Events: Conferences, workshops, and training sessions

- Online Presence: LinkedIn networking and technical discussions

- Mentorship: Both seeking mentors and mentoring others

Career Planning Strategies

- Set Clear Goals: Define short-term and long-term objectives

- Develop Diverse Skills: Combine technical and business acumen

- Seek Challenging Projects: Volunteer for high-visibility assignments

- Document Achievements: Maintain portfolio of accomplishments

Frequently Asked Questions

1. What is the difference between HPLC and UHPLC?

UHPLC (Ultra-High-Performance Liquid Chromatography) uses smaller particles (sub-2 μm) and higher pressures (up to 1500 bar) compared to HPLC (2-10 μm particles, up to 400 bar). This results in:

3-5x faster analysis times

Superior resolution and sensitivity

Higher operational costs

Better peak capacity for complex mixtures

2. Which chromatography method is best for protein analysis?

Best methods for proteins:

Size Exclusion Chromatography (SEC): Preserves native structure, determines molecular weight

Ion Exchange Chromatography: High resolution based on charge differences

Reverse Phase HPLC: High resolution but may denature proteins

Affinity Chromatography: Highest selectivity for specific proteins

Choice depends on: protein stability, required purity, analysis vs. purification goals.

3. How do I choose between GC and HPLC?

Choose GC when:

Sample is volatile or semi-volatile (boiling point <400°C)

Thermal stability is good

High resolution needed for complex mixtures

Cost-effective analysis required

Choose HPLC when:

Sample is non-volatile, polar, or thermally labile

Working with large molecules (>1000 Da)

Need aqueous compatibility

UV/visible detection is adequate

4. What causes peak tailing in chromatography?

Common causes of peak tailing:

Column overloading: Reduce injection volume

pH effects: Optimize mobile phase pH for ionizable compounds

Secondary interactions: Use ion-pairing agents or buffer additives

Column degradation: Replace worn columns

Extra-column volume: Check connections and tubing

5. How often should chromatography columns be replaced?

Column lifetime depends on:

Sample type: Clean samples last longer (5000+ injections)

Mobile phase conditions: Extreme pH reduces lifetime

Maintenance practices: Proper storage extends life

Performance criteria: Replace when resolution drops <80%

Typical lifetimes:

HPLC columns: 1000-5000 injections

GC columns: 2000-10000 injections

Preparative columns: 500-2000 injections

6. What is the detection limit in chromatography?

Detection limits vary by method:

HPLC-UV: 0.1-10 μg/mL

HPLC-MS: 0.1-1 ng/mL

GC-FID: 1-10 pg (absolute)

GC-MS: 0.1-1 pg (absolute)

LC-MS/MS: 0.01-0.1 ng/mL

Factors affecting detection limits:

Detector type and sensitivity

Sample matrix interference

Mobile phase background

Injection volume and concentration