Quick Answer Box

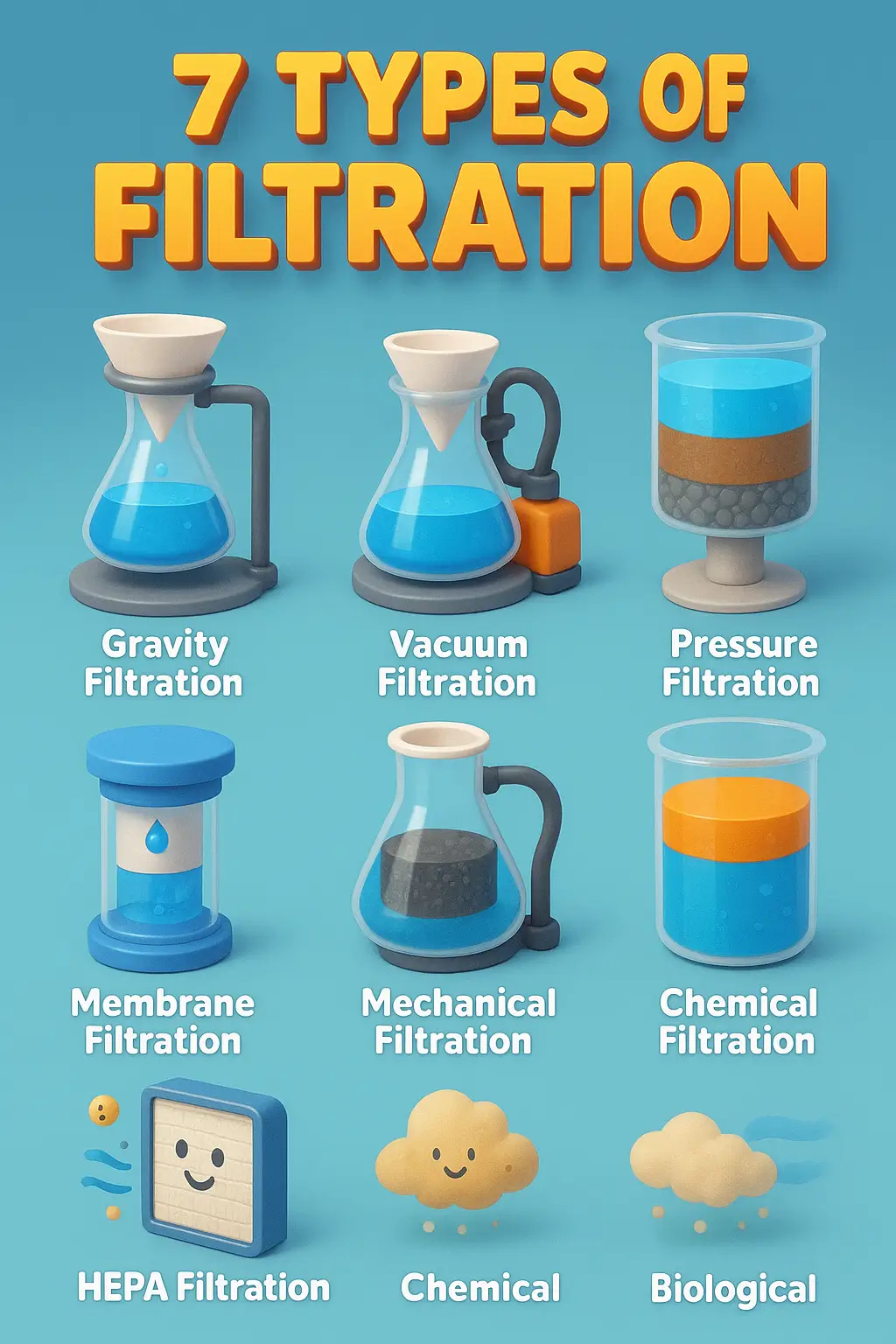

What is filtration? Filtration is a separation technique that removes solid particles from liquids or gases using physical barriers, chemical processes, or biological methods. The 7 main types are: gravity, vacuum, pressure, membrane, mechanical, chemical, and biological filtration.

Table of Contents

What is Filtration?

Filtration is a fundamental separation technique in chemistry that separates solids from liquids or gases using various physical, chemical, or biological methods. This process is essential across laboratory research, industrial manufacturing, water treatment, and countless other applications.

Why Filtration Matters in 2025

Modern filtration technology has evolved beyond simple particle removal. Today’s systems address:

- Nano-scale contaminant removal (down to 0.001 microns)

- Energy-efficient processing with reduced environmental impact

- Smart monitoring systems with IoT integration

- Regulatory compliance meeting stringent global standards

Key Point: Understanding different filtration types helps you select the most efficient method for your specific application, potentially saving 30-50% on operational costs.

7 Types of Filtration Methods

1. Gravity Filtration

How it works: Uses gravitational force to pull liquids through filter media naturally.

Best for:

- Large volume processing

- Low-pressure applications

- Cost-sensitive operations

- Emergency water treatment

Advantages: ✅ No power required

✅ Minimal maintenance

✅ Cost-effective for high volumes

✅ Simple operation

Disadvantages: ❌ Slow processing rates

❌ Requires height differential

❌ Limited pressure handling

Real-world example: Municipal water treatment plants use slow sand gravity filters to process millions of gallons daily while maintaining low operational costs.

2. Vacuum Filtration

How it works: Creates negative pressure below the filter to draw liquids through while retaining solids.

Best for:

- Laboratory applications

- Pharmaceutical manufacturing

- Analytical sample preparation

- Research environments

Advantages: ✅ Precise flow control

✅ Fast filtration rates

✅ Complete liquid removal

✅ Excellent for small batches

Disadvantages: ❌ Requires vacuum equipment

❌ Higher energy consumption

❌ Complex maintenance

Pro Tip: Vacuum filtration can reduce processing time by 60-80% compared to gravity methods for laboratory applications.

3. Pressure Filtration

How it works: Uses pumps or compressed air to force liquids through filter media under controlled pressure.

Best for:

- Industrial manufacturing

- High-throughput operations

- Viscous fluid processing

- Municipal water systems

Advantages: ✅ High processing rates

✅ Compact equipment design

✅ Precise flow control

✅ Handles thick liquids

Disadvantages: ❌ Higher energy costs

❌ Complex equipment

❌ Potential system failures

Industry insight: Modern pressure filtration systems can process up to 1000x more volume per hour than gravity methods.

4. Membrane Filtration

How it works: Uses semi-permeable membranes with precise pore sizes to separate particles at the molecular level.

Types include:

- Reverse Osmosis (RO): 0.0001-0.001 microns

- Nanofiltration (NF): 0.001-0.01 microns

- Ultrafiltration (UF): 0.01-0.1 microns

- Microfiltration (MF): 0.1-10 microns

Best for:

- Ultra-pure water production

- Pharmaceutical applications

- Food & beverage processing

- Desalination plants

Advantages: ✅ Molecular-level separation

✅ Removes bacteria & viruses

✅ Consistent output quality

✅ Highly selective

Disadvantages: ❌ High initial investment

❌ Membrane fouling issues

❌ Requires pre-treatment

Market data: The membrane filtration market is expected to reach $40.6 billion by 2026, growing at 7.3% CAGR.

5. Mechanical Filtration

How it works: Uses physical barriers like mesh, fabric, or screens to trap particles larger than the pore size.

Best for:

- HVAC systems

- Swimming pools

- Automotive filters

- General particle removal

Advantages: ✅ Simple operation

✅ Low initial cost

✅ No chemicals needed

✅ Immediate results

Disadvantages: ❌ Limited to large particles

❌ Regular replacement needed

❌ Cannot remove dissolved substances

Quick fact: Mechanical filters are the most widely used type, accounting for over 60% of all filtration applications globally.

6. Chemical Filtration

How it works: Uses chemical reactions, adsorption, or ion exchange to remove dissolved contaminants.

Common methods:

- Activated carbon: Removes odors, tastes, chlorine

- Ion exchange resins: Removes specific ions

- Chemical precipitants: Converts dissolved substances to solids

Best for:

- Water treatment plants

- Laboratory purification

- Aquarium systems

- Taste/odor removal

Advantages: ✅ Removes dissolved contaminants

✅ Targets specific pollutants

✅ Improves taste/odor

✅ High selectivity

Disadvantages: ❌ Higher operating costs

❌ Chemical media replacement

❌ Potential byproducts

Environmental note: Modern chemical filtration systems use 40% less chemicals than traditional methods while achieving better results.

7. Biological Filtration

How it works: Employs beneficial bacteria to break down organic contaminants naturally.

Best for:

- Wastewater treatment

- Aquaculture systems

- Pond maintenance

- Organic waste processing

Advantages: ✅ Environmentally friendly

✅ Self-sustaining

✅ Low energy requirements

✅ Natural process

Disadvantages: ❌ Slow establishment

❌ Temperature sensitive

❌ Limited to organic compounds

Sustainability highlight: Biological filtration reduces carbon footprint by 70% compared to chemical alternatives.

Filtration Comparison Matrix

| Method | Particle Size | Cost | Speed | Maintenance | Best Use |

|---|---|---|---|---|---|

| Gravity | 10-100+ microns | Low | Slow | Minimal | Large volumes |

| Vacuum | 0.1-50 microns | Medium | Fast | Medium | Laboratory |

| Pressure | 0.1-100+ microns | Medium | Very Fast | Medium | Industrial |

| Membrane | 0.001-10 microns | High | Medium | High | Ultra-pure |

| Mechanical | 1-100+ microns | Low | Medium | Low | General use |

| Chemical | Molecular | Medium | Slow | Medium | Water treatment |

| Biological | Organic only | Low | Very Slow | Low | Wastewater |

How to Choose the Right Filtration Method

Step-by-Step Selection Guide

1. Identify Your Contaminants

- Visible particles → Mechanical/Gravity filtration

- Dissolved substances → Chemical/Membrane filtration

- Organic compounds → Biological/Chemical filtration

- Microorganisms → Membrane/UV filtration

2. Determine Volume Requirements

- Small batches (< 1L) → Vacuum filtration

- Medium volumes (1-100L) → Pressure filtration

- Large volumes (>100L) → Gravity/Membrane systems

3. Consider Operating Constraints

- Budget-conscious → Gravity/Mechanical

- High precision needed → Membrane/Vacuum

- Energy limitations → Gravity/Biological

- Speed critical → Pressure/Vacuum

4. Evaluate Maintenance Capacity

- Minimal staff → Simple mechanical systems

- Technical expertise → Advanced membrane systems

- Remote locations → Self-cleaning systems

Decision Tree Quick Reference

Start Here → What are you filtering?

Visible particles only?

├─ Yes → Large volume?

│ ├─ Yes → Gravity Filtration

│ └─ No → Mechanical Filtration

│

└─ No → Need molecular precision?

├─ Yes → Membrane Filtration

├─ Dissolved chemicals? → Chemical Filtration

└─ Organic waste? → Biological Filtration

Applications by Industry

Water Treatment (Municipal & Industrial)

- Primary method: Multi-stage combining mechanical, chemical, and membrane

- Regulatory compliance: WHO/EPA standards

- Emerging trend: Smart monitoring with IoT sensors

Pharmaceutical Manufacturing

- Primary method: Membrane filtration (0.22 micron sterile filters)

- Critical factor: FDA validation requirements

- Innovation: Single-use systems reducing contamination risk

Food & Beverage Processing

- Primary method: Combination of mechanical and membrane

- Key application: Clarification, sterilization, concentration

- Sustainability focus: Energy-efficient membrane systems

Chemical Processing

- Primary method: Pressure filtration for high viscosity

- Specialized need: Chemical-resistant materials

- Safety priority: Containment and leak prevention

Laboratory Research

- Primary method: Vacuum filtration for precision

- Sample sizes: Typically 1mL to 1L volumes

- Automation trend: Robotic filtration systems

Common Problems & Solutions

Problem 1: Rapid Filter Clogging

Symptoms: Decreased flow rates, increased pressure Causes: Oversized particles, inadequate pre-filtration Solutions:

- Implement multi-stage pre-filtration

- Use backwash cycles (where applicable)

- Optimize particle size distribution analysis

Problem 2: Inconsistent Output Quality

Symptoms: Variable purity, breakthrough events Causes: Worn filter media, system overloading Solutions:

- Implement real-time monitoring

- Establish performance-based replacement schedules

- Use redundant filtration stages

Problem 3: High Operating Costs

Symptoms: Frequent media replacement, high energy usage Causes: Incorrect system sizing, inefficient operation Solutions:

- Conduct system optimization audit

- Consider hybrid filtration approaches

- Implement predictive maintenance

Problem 4: Membrane Fouling (Membrane Systems)

Symptoms: Rapid pressure increase, decreased permeate flow Causes: Inadequate pre-treatment, biological growth Solutions:

- Improve chemical pre-treatment

- Regular CIP (Clean-in-Place) procedures

- Anti-fouling membrane coatings

Future Trends in Filtration Technology

Smart Filtration Systems (2024-2025)

- IoT Integration: Real-time monitoring and predictive maintenance

- AI Optimization: Machine learning for process optimization

- Remote Management: Cloud-based system control

- Cost Impact: 25-30% reduction in operating costs

Sustainable Technologies

- Green Chemistry: Biodegradable filter media

- Energy Recovery: Heat exchangers in filtration systems

- Circular Economy: Filter media recycling programs

- Carbon Neutral: Zero-waste filtration processes by 2030

Nanotechnology Applications

- Nanofiber Membranes: 10x higher surface area

- Selective Nanoparticles: Targeted contaminant removal

- Self-Cleaning Surfaces: Photocatalytic filter media

- Market Growth: 15% CAGR through 2026

Hybrid Systems Integration

- Multi-Method Combinations: Optimized for complex contamination

- Modular Designs: Scalable and customizable systems

- Process Intensification: Smaller footprint, higher efficiency

- Industry Adoption: 40% of new installations by 2025

Frequently Asked Questions

What is the most efficient type of filtration?

Answer: Efficiency depends on your specific needs. Membrane filtration offers the highest precision (99.99% removal of target contaminants), while gravity filtration is most energy-efficient for large volumes. For cost-effectiveness, mechanical filtration typically provides the best value for general particle removal.

How do I know when to replace filters?

Answer: Replace filters when:

Flow rate drops below 80% of original capacity

Pressure differential increases by 50% or more

Output quality testing shows breakthrough

Manufacturer’s time-based recommendations are reached Modern systems use smart sensors to automatically signal replacement needs.

Can different filtration types be combined?

Answer: Yes, multi-stage filtration is common and often more effective than single methods. Typical combinations include:

Pre-filtration (mechanical) + Fine filtration (membrane)

Chemical treatment + Membrane polishing

Biological treatment + Chemical finishing

What’s the difference between microfiltration and ultrafiltration?

Answer: The key difference is pore size:

Microfiltration: 0.1-10 microns (removes bacteria, suspended solids)

Ultrafiltration: 0.01-0.1 microns (removes viruses, proteins, colloids) Ultrafiltration provides finer separation but requires higher pressure and costs more to operate.

How much does industrial filtration cost?

Answer: Costs vary significantly:

Simple mechanical systems: $1,000-$10,000

Pressure filtration systems: $10,000-$100,000

Advanced membrane systems: $50,000-$500,000

Operating costs: $0.10-$2.00 per 1000 gallons processed

Consider total cost of ownership including maintenance, energy, and replacement media.

What regulations apply to filtration systems?

Answer: Key regulations include:

Water treatment: EPA Safe Drinking Water Act, WHO guidelines

Food processing: FDA Food Safety Modernization Act

Pharmaceuticals: FDA Current Good Manufacturing Practice (cGMP)

Industrial: Local environmental protection standards

Always consult with regulatory experts for your specific application and location.

Conclusion

Understanding the seven types of filtration—gravity, vacuum, pressure, membrane, mechanical, chemical, and biological—is essential for selecting the right system for your specific needs. Each method offers unique advantages, from the simplicity of gravity filtration to the precision of membrane systems.

Key takeaways for 2025:

- Smart systems with IoT integration are becoming standard

- Sustainability is driving technology development

- Hybrid approaches often outperform single-method systems

- Total cost of ownership matters more than initial price

Whether you’re upgrading existing systems or planning new installations, consider consulting with filtration specialists who understand current regulations and emerging technologies. The right filtration system not only protects your investment but also ensures compliance with increasingly stringent quality standards.

Related Topics:

Citations & Sources:

- International Water Association – Membrane Technology Guidelines

- EPA Filtration Standards – 2024 Update

- Journal of Membrane Science – Recent Advances in Filtration

- World Health Organization – Water Treatment Recommendations